Send My Request

Ultimate Guide to Engineered Plastic Components in 2026

A deep dive into engineered plastic components for 2026. This guide covers the critical distinctions between engineering and commodity plastics, details high-performance materials like PEEK and Nylon, explores automotive applications including engine covers, and analyzes future trends in sustainability and manufacturing.

- Introduction

- The Core Difference: Engineered vs. Commodity Plastics

- Industrial vs. Hobbyist Applications

- Key Engineering Plastic Materials

- 1. PEEK (Polyether Ether Ketone)

- 2. Nylon (Polyamide - PA)

- 3. Polycarbonate (PC)

- 4. ABS (Acrylonitrile Butadiene Styrene)

- Strategic Design & Manufacturing Considerations

- Design for Manufacturability (DFM)

- Manufacturing Processes

- Quality Assurance and Standards

- Applications: The Automotive Shift

- Future Trends: 2026 and Beyond

- Frequently Asked Questions

- What defines an "engineered plastic" compared to standard plastic?

- Why are engineered plastics used for engine covers?

- Can engineered plastic components be recycled?

- What is the most heat-resistant engineering plastic?

- How do I choose the right manufacturing process?

- References

Introduction

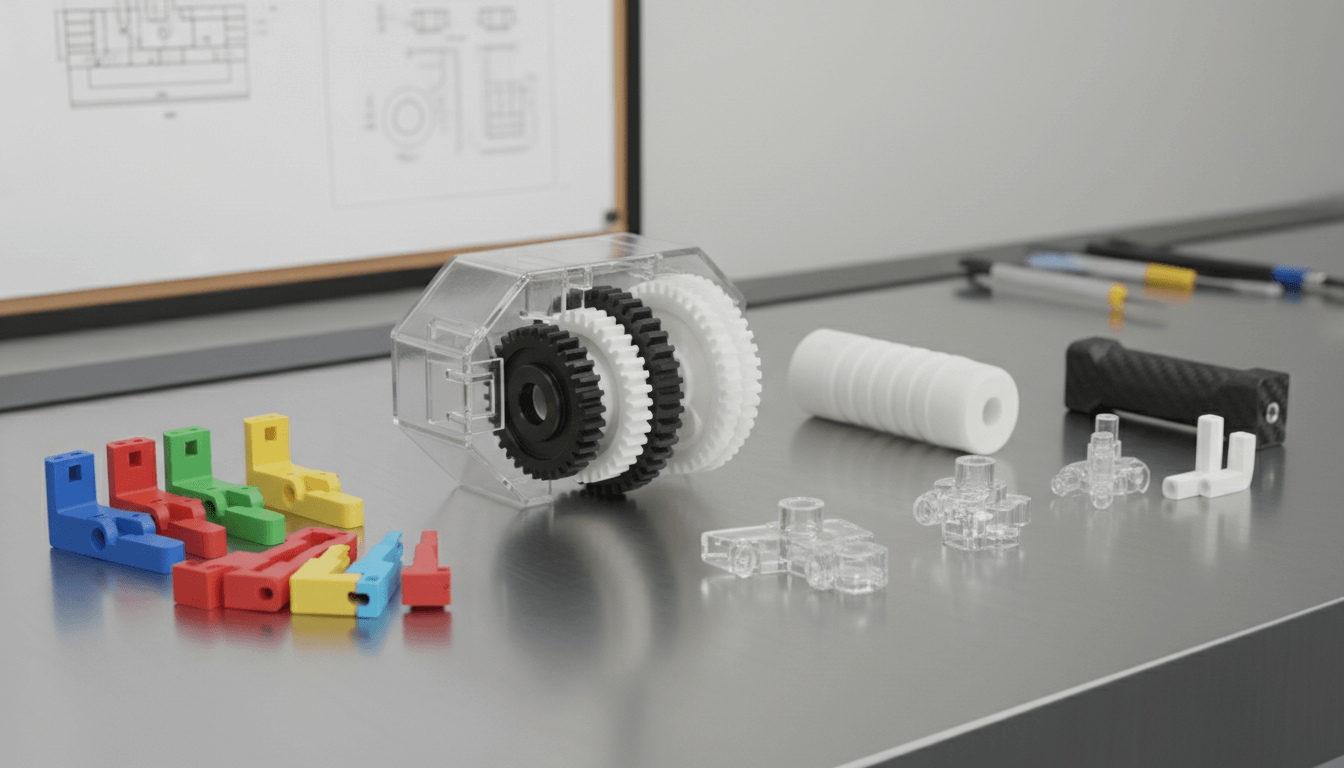

In the realm of modern manufacturing, engineered plastic components have transcended their role as mere alternatives to metal, becoming the primary choice for mission-critical applications in aerospace, automotive, and medical industries. Unlike the generic polymers used in single-use packaging, engineering plastics are high-performance materials designed to withstand extreme mechanical stress, aggressive chemicals, and elevated temperatures.

As we approach 2026, the demand for these materials is being driven by the electric vehicle (EV) revolution and the push for sustainability. This guide provides a technical deep dive into plastic engineering, offering senior engineers and procurement professionals the insights needed to navigate material selection, design challenges, and the future of engineered plastic technology.

The Core Difference: Engineered vs. Commodity Plastics

To effectively select materials, one must understand the fundamental divergence between engineering plastic and commodity plastic. As noted by Xometry, the primary distinction lies in the molecular structure and performance capabilities. Commodity plastics (like PE, PP, PVC) are typically semi-crystalline or amorphous polymers with lower mechanical strength, suitable for high-volume, low-stress applications.

Engineering plastics, conversely, are formulated with distinct polymer backbones that offer superior thermal and mechanical stability. For instance, according to DXTSEALS, while a commodity plastic might degrade at temperatures below 100°C, an engineering plastic material like PEEK can maintain structural integrity at continuous service temperatures exceeding 250°C. This capability makes them indispensable for components that must endure rigorous operating environments where failure is not an option.

Industrial vs. Hobbyist Applications

It is crucial to distinguish industrial-grade materials from those used in consumer hobbies. The polystyrene typically found in fire engine plastic model kits or static plastic models of engines lacks the thermal stability, fatigue resistance, and creep resistance required for functional industrial parts. While a hobbyist's plastic engine cover is designed for aesthetics, an automotive engine cover plastic component must dampen noise, resist under-hood heat cycles, and withstand chemical exposure to fuels and lubricants.

Key Engineering Plastic Materials

Selecting the right polymer is an exercise in balancing performance trade-offs. The following materials represent the cornerstone of current plastic engineering:

1. PEEK (Polyether Ether Ketone)

Regarded as one of the highest-performing thermoplastics, PEEK offers exceptional chemical resistance and thermal stability. According to data from MatWeb, PEEK's heat deflection temperature (HDT) can exceed 150°C even without reinforcement, and glass-filled grades push this significantly higher. It is the material of choice for aerospace connectors and medical implants.

2. Nylon (Polyamide - PA)

Nylon is renowned for its high tensile strength and wear resistance. It is frequently used in high-friction environments, such as gears and bearings. In the automotive sector, glass-filled Nylon is the standard for intake manifolds and plastic cover for engine applications due to its resistance to hydrocarbons.

3. Polycarbonate (PC)

Known for its high impact strength and optical clarity, Polycarbonate is virtually unbreakable in standard applications. It is widely used in protective housings and lenses, although it has lower chemical resistance compared to PEEK or Nylon.

4. ABS (Acrylonitrile Butadiene Styrene)

ABS provides a balanced profile of toughness, rigidity, and processability. While not suited for extreme heat, its dimensional stability makes it ideal for consumer electronics and automotive interior parts.

Strategic Design & Manufacturing Considerations

Design for Manufacturability (DFM)

Successful engineered plastic components begin with rigorous DFM. Engineers must account for shrinkage rates, which vary significantly between amorphous and semi-crystalline plastics. For example, ignoring draft angles or uneven wall thickness can lead to warpage and sink marks, compromising the part's geometric tolerances.

Manufacturing Processes

· Injection Molding: The standard for high-volume production. When scaling up, selecting engineered plastic components for high-volume production requires careful tooling design to manage the specific flow characteristics of engineering resins.

· CNC Machining: Ideal for prototyping and low-volume runs where high precision is required without the initial tooling investment.

· Additive Manufacturing: As noted by Fortune Business Insights, 3D printing is revolutionizing the sector, allowing for the creation of complex geometries with high-performance materials like ULTEM and PEEK that were previously impossible to mold.

Quality Assurance and Standards

Reliability is verified through standardized testing. The ASTM D638 standard is the global benchmark for determining the tensile properties of plastics, while ASTM D648 measures the heat deflection temperature under load. Adherence to these standards ensures that an engineered plastic part will perform predictably under real-world stress.

Applications: The Automotive Shift

The automotive industry remains the largest consumer of engineering plastics. The drive for lightweighting—crucial for extending EV range—has led to the replacement of metal components with plastic equivalents.

· Under-the-Hood: The plastic engine cover is a prime example. Modern engine cover plastic formulations are often reinforced with mineral or glass fibers to provide acoustic damping and thermal resistance.

· Structural: High-strength composites are now used for front-end modules and bumper beams.

· Interior: Engineered plastic components in the cabin reduce weight while meeting strict flammability and volatile organic compound (VOC) standards.

Future Trends: 2026 and Beyond

Looking ahead to 2026, the engineering plastics market is poised for significant evolution. According to Mordor Intelligence, the market size is expected to reach nearly 80 million tons by 2030. Key trends include:

1. Sustainable Formulations: A shift toward bio-based polyamides and chemically recycled PEEK to reduce carbon footprints without sacrificing performance.

2. Smart Polymers: Integration of conductive additives to create plastic components that can shield against electromagnetic interference (EMI) or dissipate heat in high-power electronics.

3. Metal Replacement: Continued expansion into structural applications previously dominated by aluminum and steel, driven by advanced composite technologies.

Frequently Asked Questions

What defines an "engineered plastic" compared to standard plastic?

Engineered plastics are a group of plastic materials that have better mechanical and thermal properties than widely used commodity plastics (such as polystyrene, PVC, polypropylene, and polyethylene). They are designed for technical applications requiring high strength, heat resistance, and chemical stability.

Why are engineered plastics used for engine covers?

Manufacturers use engineered plastic for plastic cover for engine applications because they offer significant weight reduction compared to metal, excellent thermal insulation, and superior noise, vibration, and harshness (NVH) damping properties.

Can engineered plastic components be recycled?

Yes, many thermoplastic engineering plastics (like Nylon, PC, and PET) can be mechanically or chemically recycled. However, high-performance thermosets or composites with glass fiber reinforcement present more complex recycling challenges that the industry is actively solving.

What is the most heat-resistant engineering plastic?

PEEK (Polyether Ether Ketone) and Polyimide are among the most heat-resistant thermoplastics available, capable of withstanding continuous service temperatures above 250°C (480°F).

How do I choose the right manufacturing process?

Selection depends on volume and geometry. CNC machining is best for low-volume, high-precision parts. Injection molding is ideal for mass production. 3D printing is suitable for complex prototypes and custom low-volume runs.

References

· Xometry: All About Engineering Plastics: Definition, Importance, Uses, Properties, and Types

· MatWeb: Heat Deflection Temperature Testing of Plastics

· Fortune Business Insights: Engineering Plastics Market Size, Growth

· Mordor Intelligence: Engineering Plastics Market Size & Share Analysis

Recommended for you

FAQ

FAQs

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

You may also like

The plastic plug manufactured by Insert molding with stainless steel plate

The Bost custom PPO flow valve by injection molding

The Bost custom plastic handle by injection molding with high performance PPS material

The Bost custom flow meter by injection molding with PES plastic

Leave a Message

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code