Send My Request

Customizing PP Plastic Spacers: Design Tips for Manufacturers

- Customizing PP Plastic Spacers: Design Tips for Manufacturers

- Why choose a plastic spacer — and why PP?

- Understand the material: polypropylene properties that matter for plastic spacer design

- Define functional requirements for the plastic spacer

- Geometry and wall-thickness guidelines for injection molded PP spacers

- Dimensional tolerances, fits and fastening interfaces for plastic spacer parts

- Tooling and gating strategies for consistent PP plastic spacer production

- Material variants and additives: tailoring PP for spacer performance

- Surface finish, aesthetics and labeling for plastic spacers

- Quality control, testing and validation of PP plastic spacers

- Cost optimization strategies for injection molded PP spacers

- Assembly considerations and fastener compatibility for plastic spacers

- Sustainability and end-of-life strategies for PP plastic spacers

- Comparing common spacer materials — quick reference table

- Brand strengths: why choose our PP plastic spacer by injection molding

- Practical checklist before launch: ensure production readiness

- FAQ — Frequently asked questions about PP plastic spacers

- Q1: Can PP spacers be used outdoors?

- Q2: Are PP spacers suitable for electrical insulation?

- Q3: When should I choose glass-filled PP for spacers?

- Q4: What tolerances can I expect from injection-molded PP spacers?

- Q5: How do I mark or print on PP spacers?

- Q6: Are recycled PP materials suitable for spacers?

- Contact us / View product

- References and authoritative resources

Customizing PP Plastic Spacers: Design Tips for Manufacturers

Why choose a plastic spacer — and why PP?

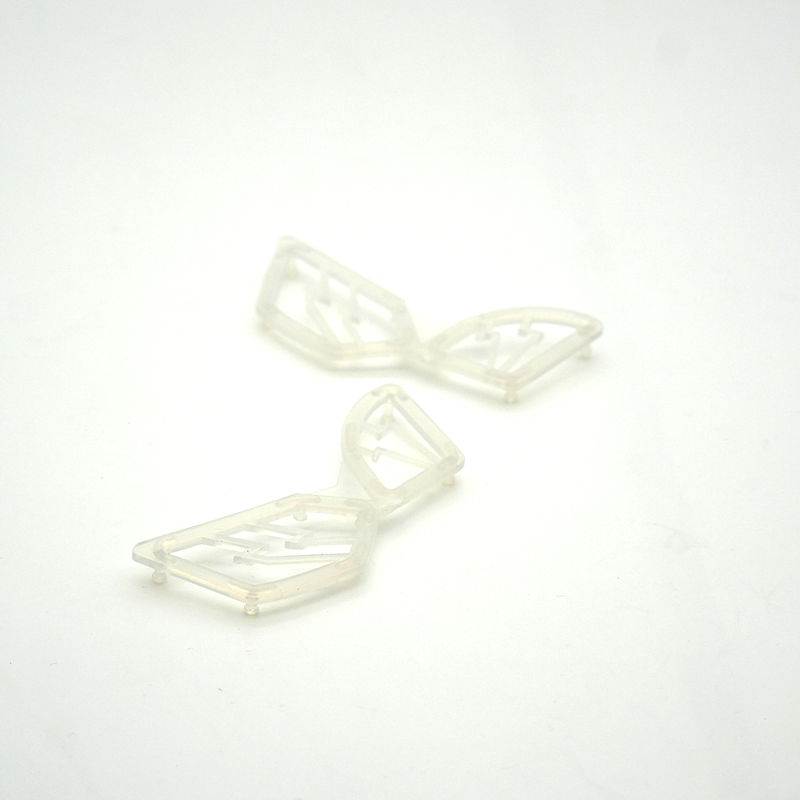

Plastic spacer components play a simple but critical role in many assemblies: they set distances, provide electrical isolation, reduce friction, and support fasteners. Choosing polypropylene (PP) for spacers balances cost, chemical resistance, and manufacturability. A PP plastic spacer by injection molding is especially attractive for high-volume runs because injection molding supports tight tolerances, repeatability, and complex features at low per-piece cost.

This article offers practical, field-tested guidance for engineers and product teams who need to design and produce plastic spacer parts. It addresses materials, geometry, tooling, production and quality control — all with an eye toward minimizing risk and controlling cost while meeting functional requirements.

Understand the material: polypropylene properties that matter for plastic spacer design

Design decisions for a plastic spacer begin with PP material behavior. Key polypropylene traits that influence design:

- Low density: lightweight spacer compared with many engineering plastics.

- Chemical resistance: good resistance to many acids, bases, and solvents common in consumer and industrial environments.

- Low moisture uptake: PP retains properties better than hygroscopic polymers (e.g., nylon), simplifying dimensional control.

- Moderate stiffness and strength: adequate for many spacer loads but weaker than PC or POM — design accordingly.

- Good fatigue and impact resistance: useful where repeated load cycles occur.

When specifying a PP plastic spacer by injection molding, choose a specific PP grade (homopolymer vs copolymer; impact-modified; glass-filled) based on strength, stiffness, and environmental demands. If the spacer must bear heavy loads or tight stiffness constraints, consider glass-filled PP or alternate polymers. Custom designs can affect production planning, making lead time and MOQ strategies for PP plastic spacer procurement a critical consideration during supplier negotiations.

References: polypropylene material data from Plastics industry sources and material datasheets (see References section).

Define functional requirements for the plastic spacer

Every spacer should begin with a clear functional specification. Ask and document:

- What is the primary function (standoff, insulator, bearing, fastener spacer)?

- Static and dynamic loads (axial, shear, bending) and safety factor.

- Temperature range and exposure to chemicals/UV.

- Required electrical properties (insulation, dielectric strength).

- Dimensional tolerance and interface fit (press-fit, slip-fit, threaded).

- Quantity and expected lifecycle (single use, maintenance cycles).

Use these inputs to select PP grade and inform geometry. For example, a spacer that must insulate electronics and resist solvents can often use unfilled PP, whereas a load-bearing spacer may need glass-filled PP to meet stiffness requirements.

Geometry and wall-thickness guidelines for injection molded PP spacers

Proper geometry reduces injection molding defects and ensures performance.

- Uniform wall thickness: Target uniform wall sections where possible (typical PP thickness 1.5–4.0 mm for spacers). Sudden thickness changes cause sink marks and warpage.

- Minimize thickness extremes: Thin walls reduce cycle time and cost but risk short shots or weak sections; thick walls increase shrinkage and sink. Find a balance based on part size.

- Add ribs, fillets, and gussets: Use ribs to increase stiffness without adding thickness. Keep rib thickness at ~50–60% of adjacent wall thickness and add fillets to reduce stress concentration.

- Include draft: Provide draft angles (0.5–2° or more depending on texture) on walls to ease ejection.

- Avoid long unsupported cantilevers: They are prone to warpage and breakage.

These practices help ensure consistent quality for your PP plastic spacer by injection molding.

Dimensional tolerances, fits and fastening interfaces for plastic spacer parts

Tolerance planning is critical for functional fit and assembly efficiency.

- Typical tolerances: For non-critical dimensions, ±0.2–0.5 mm is common for molded PP parts. For critical mating features, tighter tolerances may be required; plan for post-molding machining if necessary.

- Hole sizes and press-fits: Account for PP shrinkage (typically 1–2% depending on grade and geometry). Use empirical fit tables or validate with prototypes. For interference fits, design keyed features or metal inserts if repeatable high force is required.

- Threaded interfaces: Prefer molded-in boss geometries designed for self-tapping screws or use heat-set/ultrasonic metal inserts for higher thread strength.

Prototype early and measure actual molded shrinkage and feature variation. Adjust tooling or part geometry to achieve consistent fits.

Tooling and gating strategies for consistent PP plastic spacer production

Injection molding tooling decisions affect cost, lead time, and part quality.

- Gate location: Place gates where flow fills the mold uniformly and where cosmetic requirements are least critical. For symmetrical spacers, center or edge gates may work depending on flow balance.

- Runner and gate size: Proper sizing prevents freeze-off and short shots. Use cold runners or hot runner systems based on production volume and cost trade-offs.

- Venting and cooling: Adequate venting prevents burn marks; evenly distributed cooling channels lower cycle times and reduce warpage.

- Tool steel and surface finish: For long runs, invest in hardened tool steel and specify surface finish; textured surfaces hide mold lines and reduce ejection force.

Tooling costs are a trade-off: higher upfront tooling investment reduces per-part cost for large volumes. For low-volume runs, consider prototype tooling or injection molding services with shared tooling.

Material variants and additives: tailoring PP for spacer performance

Select a PP variant to meet specific performance goals:

- Homopolymer vs random copolymer: Copolymers have improved impact at low temperatures and better processing for thin-walled parts.

- Glass-filled PP: Increases stiffness and dimensional stability but reduces impact resistance and increases tool wear.

- Mineral-filled PP: Reduces cost and improves stiffness with less abrasive wear than glass.

- Impact modifiers: Improve toughness for drop or shock resistance.

- Stabilizers and UV inhibitors: Required for outdoor applications to prevent embrittlement and oxidation.

When adding fillers or reinforcements, update mold venting, gate design and cooling to handle higher viscosity melts.

Surface finish, aesthetics and labeling for plastic spacers

Surface considerations often matter for consumer or visible applications.

- Texture: Mold textures hide flow lines and small imperfections. Higher texture increases draft required for ejection.

- Overmolding or two-shot molding: For spacers needing rubberized surfaces or sealing features, consider two-shot processes.

- Printing and labeling: Pad printing or laser marking can add logos or part numbers—work with marker suppliers to ensure adhesion on PP (PP is non-polar and requires surface treatment like corona or flame treatment for printing).

Plan surface finish early to avoid costly tool revisions.

Quality control, testing and validation of PP plastic spacers

A robust validation plan ensures reliable parts in the field.

- Dimensional inspection: Use CMM or optical inspection for critical dimensions and first-article inspections.

- Mechanical testing: Test tensile, compression and fatigue when spacers carry loads. Use representative assemblies to validate performance.

- Environmental testing: Heat-aging, chemical exposure, and UV exposure tests validate long-term behavior.

- Process control: Implement SPC (statistical process control) on cycle time, melt temperature, and cavity pressure to detect drift early.

Document acceptance criteria and maintain traceability for high-value or safety-critical spacers.

Cost optimization strategies for injection molded PP spacers

Balancing cost and quality is crucial.

- Simplify geometry: Reduce undercuts, complex cores, and large bosses to lower tooling complexity.

- Increase cavity count: More cavities per tool reduce per-part tooling amortization but increase tool complexity.

- Use hot-runner systems: They reduce material waste and shorten cycle time in medium to high volumes.

- Standardize parts: Design modular spacers that cover multiple product variants to increase volumes and reduce SKUs.

A unit-cost analysis (tooling amortization + material + cycle time + labor) helps select the best manufacturing approach.

Assembly considerations and fastener compatibility for plastic spacers

Design spacers with assembly methods in mind:

- Self-locating features: Add chamfers or lead-ins to simplify automated or manual assembly.

- Snap fits vs screws: Snap features reduce hardware cost but require precise dimensions and life-cycle validation.

- Metal inserts: Consider molded-in threaded inserts for frequent assembly/disassembly or where high torque is applied.

Work with assembly engineers early to ensure the spacer design minimizes assembly time and failure modes.

Sustainability and end-of-life strategies for PP plastic spacers

Sustainability is increasingly important in supply chains.

- Recycled PP: Many spacers can use post-industrial or post-consumer recycled PP where color and mechanical property trade-offs are acceptable.

- Design for disassembly: Make spacers easy to separate from other materials to support recycling.

- Lightweighting: Reduce material through geometry optimization without compromising strength.

Document material composition and provide guidance for recyclers to support circular design.

Comparing common spacer materials — quick reference table

| Property | PP (unfilled) | PP (glass-filled) | Nylon (PA) | POM (Acetal) |

|---|---|---|---|---|

| Density (g/cm3) | ~0.90 | 1.0–1.4 (depends on fill) | ~1.13 | ~1.41 |

| Tensile strength (MPa) | 25–35 | 50–120 | 50–90 | 60–70 |

| Moisture sensitivity | Low | Low | High | Low |

| Typical cost | Low | Medium | Medium | High |

| Best use | Electrical insulation, light-duty spacers | Load-bearing spacers needing stiffness | High wear, higher strength needs | High precision, low friction |

Notes: Values are illustrative ranges based on typical datasheets and industry references. Exact performance depends on grade and additives.

Brand strengths: why choose our PP plastic spacer by injection molding

As an experienced supplier of injection-molded components, our advantages include:

- Material expertise: We guide grade selection (homopolymer, copolymer, glass-filled) and recommend suitable additives for UV resistance and chemical exposure.

- Tooling competence: In-house tooling design and simulation reduce first-article iterations and lower time-to-market.

- Quality systems: We apply SPC, first-article inspection, and mechanical testing to meet specified tolerances and validate performance.

- Cost-effective production: Volume strategies—multi-cavity tools and hot-runner systems—optimize unit costs for large runs.

- Sustainability options: We support recycled PP streams and provide end-of-life guidance on recyclability and labeling.

These capabilities ensure your PP plastic spacer by injection molding meets functional, aesthetic and cost targets reliably.

Practical checklist before launch: ensure production readiness

Before full production run, verify the following:

- Material grade and supplier approved.

- Tool design and gating validated with mold flow analysis.

- Prototype parts tested for dimensional accuracy and mechanical performance.

- Assembly trials completed and insertion/torque requirements validated.

- Quality plan (AQL, inspection points) defined.

- Environmental and regulatory requirements (e.g., RoHS) confirmed.

Completing this checklist reduces surprises in ramp-up and supports predictable cost and lead times.

FAQ — Frequently asked questions about PP plastic spacers

Q1: Can PP spacers be used outdoors?

A1: Yes, but unmodified PP degrades under long-term UV exposure. Use UV-stabilized grades or add UV inhibitors; consider protective coatings for extended lifespan.

Q2: Are PP spacers suitable for electrical insulation?

A2: Yes. PP has good dielectric properties and low moisture uptake, making it suitable for many insulation applications. Confirm dielectric strength requirements against material datasheets.

Q3: When should I choose glass-filled PP for spacers?

A3: Choose glass-filled PP when higher stiffness, reduced creep, and better dimensional stability are required. Note: fillers increase abrasion on tooling and may affect impact strength and surface finish.

Q4: What tolerances can I expect from injection-molded PP spacers?

A4: Typical tolerances are ±0.2–0.5 mm for non-critical dimensions. Tight tolerances are achievable with careful design, controlled molding conditions, and post-mold machining if needed.

Q5: How do I mark or print on PP spacers?

A5: PP is non-polar and resists inks. Use surface treatment (corona or flame), primers, or laser marking. For logos, consider pad printing with appropriate adhesives or thermal transfer after surface treatment.

Q6: Are recycled PP materials suitable for spacers?

A6: Post-industrial recycled PP is often suitable if mechanical and aesthetic requirements are met. Post-consumer recycled PP can vary more and requires validation for critical applications.

Contact us / View product

If you need engineering support or samples for a PP plastic spacer by injection molding, contact our technical sales team. We offer design reviews, material recommendations, prototyping, and full-scale production services. Request a quote or a free design consultation today.

References and authoritative resources

- Polypropylene — Wikipedia: https://en.wikipedia.org/wiki/Polypropylene

- Injection molding — Wikipedia: https://en.wikipedia.org/wiki/Injection_molding

- PlasticsEurope — Polypropylene factsheet: https://www.plasticseurope.org/en/about-plastics/what-are-plastics/large-family/polypropylene

- MatWeb material property database — PP datasheets: https://www.matweb.com

- ISO/ASTM standards information (general reference): https://www.iso.org and https://www.astm.org

top high-performance polymers for medical devices 2026

Electrical Insulation Advantages of ABS Connectors

Plastic Bushing Materials Explained: Why Choose PE?

Maintenance Best Practices for Long-Lasting Plastic Bushings

FAQs

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

The plastic plug manufactured by Insert molding with stainless steel plate

The Bost custom PPO flow valve by injection molding

The Bost custom plastic handle by injection molding with high performance PPS material

The Bost custom flow meter by injection molding with PES plastic

Get in touch with Bost

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code