Send My Request

How Injection Molding Improves PP Plastic Spacer Production

- How Injection Molding Improves PP Plastic Spacer Production

- Why choose injection molded plastic spacer solutions?

- Precision and dimensional consistency with PP plastic spacer by injection molding

- Repeatability reduces assembly and inspection costs

- Design flexibility and part integration for plastic spacer solutions

- Optimizing geometry and wall thickness

- Cost-efficiency and scalability of PP plastic spacer by injection molding

- Breakdown of cost drivers

- Quality control and testing for reliable plastic spacer parts

- Traceability and batch control

- Material advantages: why polypropylene (PP) works for spacers

- Sustainability and recyclability

- Comparing manufacturing methods: injection molding vs alternatives for plastic spacer production

- Production best practices for PP plastic spacer by injection molding

- Tooling considerations

- Automation and post-processing for scalable spacer manufacturing

- Brand advantages: why partner with us for PP plastic spacer by injection molding

- Common challenges and how injection molding solves them

- FAQs — Production and selection of PP plastic spacer by injection molding

- Q1: What makes PP suitable for spacers instead of other plastics?

- Q2: At what volume does injection molding become cost-effective for a plastic spacer?

- Q3: Can inserts or metal components be overmolded into a PP plastic spacer?

- Q4: How does regrind affect performance of PP spacers?

- Q5: What lead times should I expect from design to production?

- Contact us / View product

- Authoritative references

How Injection Molding Improves PP Plastic Spacer Production

Why choose injection molded plastic spacer solutions?

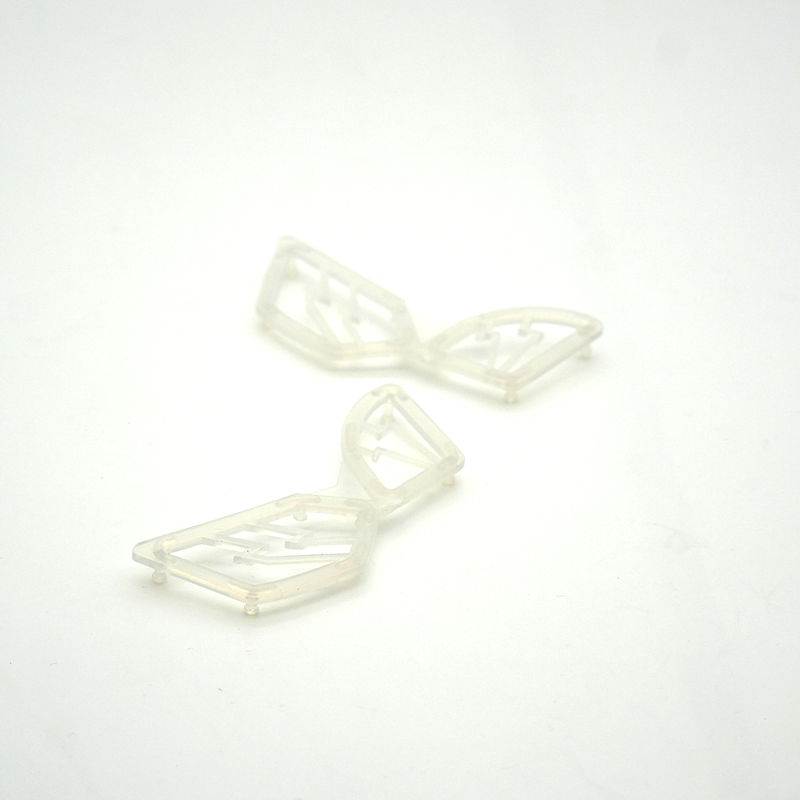

The term plastic spacer covers many small components used to maintain distance, isolate parts, or support assemblies across electronics, automotive, construction, and consumer products. For manufacturers and design engineers seeking consistent dimensional accuracy and low per-part cost, a PP plastic spacer by injection molding is often the best choice. Injection molding excels at producing complex geometries, tight tolerances, and high volumes with minimal post-processing — advantages that match the practical needs of plastic spacer production.

Precision and dimensional consistency with PP plastic spacer by injection molding

One of the primary advantages of injection molding is the ability to deliver tight dimensional control across long production runs. Polypropylene (PP) flows easily when heated and freezes quickly, making it suitable for thin-walled spacers and features such as ribs, snaps, and standoffs. A PP plastic spacer by injection molding maintains consistent dimensions part-to-part due to the repeatable nature of the process: the same mold cavity fills under controlled pressure and temperature each cycle, which reduces scrap and assembly issues downstream.

Repeatability reduces assembly and inspection costs

High repeatability also reduces inspection burden. When production is validated and monitored with statistical process control (SPC), manufacturers can minimize incoming inspection and speed parts into assembly. For customers, this means fewer delays and predictable lead times for plastic spacer orders.

Design flexibility and part integration for plastic spacer solutions

Injection molding allows designers to incorporate multiple functions into a single PP plastic spacer by injection molding — for example, integrated clips, ribs for stiffness, or snap-fit features — eliminating the need for secondary parts or fasteners. This integration simplifies assemblies, reduces SKU count, and often lowers total system cost. Because molds can form complex undercuts and precise features, designers can optimize spacers for weight, material usage, and performance.

Optimizing geometry and wall thickness

Using computer-aided engineering (CAE) tools such as mold flow analysis, engineers can optimize wall thickness and gate location to avoid sink marks, warpage, and weld lines in spacers. For PP, targeted cooling strategies and balanced flow paths ensure uniform shrinkage, which is critical for stacked or multi-component assemblies.

Cost-efficiency and scalability of PP plastic spacer by injection molding

While tooling for injection molding (mold design and fabrication) represents an upfront investment, the per-part cost becomes highly attractive at scale. For plastic spacer production — where parts are often needed in thousands to millions — injection molding lowers cost per unit through fast cycle times, automation, and minimal finishing operations.

Breakdown of cost drivers

Key cost drivers include mold complexity, material price, cycle time, and degree of automation. PP has a competitive raw material price among engineering and commodity plastics and is well-suited to high-speed molding. As production volumes rise, fixed tooling cost is amortized over larger quantities, delivering lower part cost compared with machining, hand assembly, or low-volume molding methods.

Quality control and testing for reliable plastic spacer parts

Injection molding production lines can incorporate inline monitoring and automated inspection for consistent quality. Techniques such as in-mold sensors, cavity pressure monitoring, and vision systems catch process drift early. For PP plastic spacer by injection molding targeted quality tests include dimensional verification, mechanical property testing (tensile, flexural), and functional fit checks in assembly fixtures.

Traceability and batch control

Good manufacturing practice includes lot serialization, material certificate tracking, and retained sample testing. These controls are especially important for customers in regulated sectors (medical devices, automotive), where traceable documentation and supplier audits are required.

Material advantages: why polypropylene (PP) works for spacers

Polypropylene is a favored material for spacers due to its balance of mechanical properties, chemical resistance, and low density. PP offers good fatigue resistance, low moisture absorption, and compatibility with various additives (UV stabilizers, flame retardants, colorants). For non-structural or semi-structural spacer applications, the stiffness and toughness of PP provide robust performance at low weight.

Sustainability and recyclability

PP is widely recyclable (recycling code 5) and benefits from an established recycling stream in many regions. Injection molding also produces low material waste when runners are reprocessed. Choosing a PP plastic spacer by injection molding can therefore contribute to lower embodied carbon and improved product circularity when design and material selection are aligned with recycling practices.

Comparing manufacturing methods: injection molding vs alternatives for plastic spacer production

Different manufacturing methods suit different volumes, geometries, and cost targets. The following table summarizes typical trade-offs when producing plastic spacers.

| Method | Best use case | Volume | Typical advantages | Limitations |

|---|---|---|---|---|

| Injection molding | Complex shapes, integrated features, finished parts | Medium to very high | Low per-part cost at scale, high precision, fast cycle | Upfront tooling cost, longer lead time to first part |

| Extrusion + cutting | Simple constant-cross-section spacers (tubes, strips) | Low to high | Lower tooling cost for simple shapes, continuous production | Limited geometry, secondary cutting/finishing required |

| CNC machining | Prototypes, low-volume metal/plastic spacers | Very low | Flexible for small runs and metal parts, no tooling | High per-part cost, slower, material waste |

| 3D printing (additive) | Prototypes, complex low-volume geometries | Very low | No tooling, rapid iteration | Poor surface finish, higher cost, limited material choices |

For most production-level spacer demands, injection molding of PP offers the best balance of design freedom, repeatability, and cost-efficiency.

Production best practices for PP plastic spacer by injection molding

To achieve consistent quality and performance, follow these industry best practices:

- Start with design-for-manufacturing (DFM) reviews to optimize wall thickness, draft angles, and gate placement.

- Use mold flow analysis to predict filling, cooling, and potential weld lines.

- Select appropriate PP grade (homopolymer vs copolymer) based on stiffness vs impact needs.

- Implement cavity pressure or temperature sensors to monitor shot consistency.

- Set up SPC metrics for critical dimensions and material properties.

- Plan runner design and regrind policies to minimize contamination and maintain mechanical properties.

Tooling considerations

Invest in high-quality tooling materials and surface finishes to extend mold life and reduce maintenance. For multi-cavity molds, balance flow to ensure uniform filling and consistent shrinkage across cavities. Consider family molds only when parts require identical process conditions to avoid quality variation.

Automation and post-processing for scalable spacer manufacturing

Automation further improves the economics and repeatability of injection molded PP spacers. Robotic part removal, in-mold labeling, automated finishing, and vision inspection remove human variability and speed cycle throughput. For spacers that require secondary operations (e.g., ultrasonic welding, insert placement), integrating these steps into assembly lines minimizes handling and lead time.

Brand advantages: why partner with us for PP plastic spacer by injection molding

When selecting a supplier for PP plastic spacer by injection molding, consider capabilities that reduce your risk and time-to-market. Our strengths include:

- Extensive mold design and tooling experience for multi-cavity and family molds, reducing cycle time and unit cost.

- In-house material expertise across polypropylene grades, including compounding and additive selection for UV or flame resistance.

- Quality systems aligned with industry standards (ISO 9001 and SPC practices) and a validated lab for dimensional and mechanical testing.

- Production automation and capacity for high-volume runs, coupled with flexible small-batch capabilities for product validation.

- Sustainability practices: runner regrind management, options for post-industrial recycled PP, and guidance on end-of-life recycling.

These capabilities translate into reliable delivery of functionally optimized plastic spacer parts and predictable cost profiles for customers across sectors.

Common challenges and how injection molding solves them

Common challenges when producing spacers include warpage, dimensional drift, inconsistent surface finish, and assembly misfit. Injection molding addresses these by controlling thermal cycles, using optimized tooling cooling, and leveraging material selection to balance stiffness and shrinkage. Process monitoring and mold maintenance programs help prevent drift over long production runs.

FAQs — Production and selection of PP plastic spacer by injection molding

Q1: What makes PP suitable for spacers instead of other plastics?

A1: Polypropylene offers a good combination of low density, chemical resistance, fatigue resistance, and low cost. It is especially effective for non-structural to semi-structural spacers where toughness and low weight are priorities.

Q2: At what volume does injection molding become cost-effective for a plastic spacer?

A2: Break-even depends on part complexity and tooling cost. Generally, injection molding becomes cost-effective for thousands to tens of thousands of parts per year compared to machining or low-volume methods. Run a cost analysis considering tooling amortization, cycle time, and material.

Q3: Can inserts or metal components be overmolded into a PP plastic spacer?

A3: Yes. Overmolding and insert molding are common to integrate metal threads, nuts, or alignment features within a single PP plastic spacer by injection molding. Proper material and process design are required to ensure adhesion and avoid thermal stress.

Q4: How does regrind affect performance of PP spacers?

A4: Controlled use of regrind can reduce material cost without significant performance loss. However, limit regrind percentage per resin supplier recommendations, monitor mechanical properties, and avoid contamination to preserve part performance.

Q5: What lead times should I expect from design to production?

A5: Typical lead times include 2–6 weeks for mold design and tooling (simple molds) up to 8–16 weeks for complex multi-cavity molds. Prototype runs or 3D-printed molds can speed initial validation. Once tooling is validated, cycle times are short and production lead times depend on order quantity and factory capacity.

Contact us / View product

Once the role of injection molding is clear, buyers looking to scale should focus on reducing costs with high-volume PP plastic spacer sourcing without compromising performance.If you are evaluating options for a plastic spacer or need a quote for a PP plastic spacer by injection molding, contact our sales engineering team for a DFM review, material recommendation, and cost estimate. View product samples or request a prototype today to assess fit and performance in your application.

Authoritative references

Sources used for technical context and industry background:

- Injection molding — Wikipedia: https://en.wikipedia.org/wiki/Injection_molding

- Polypropylene — Wikipedia: https://en.wikipedia.org/wiki/Polypropylene

- Plastics: Materials and Uses — PlasticsEurope: https://www.plasticseurope.org

- Society of Plastics Engineers / Plastics Industry Association: https://www.plasticsindustry.org

- ISO 9001 Quality Management Systems — ISO: https://www.iso.org/iso-9001-quality-management.

How to Choose Engineering Plastic for Mechanical Parts

PEEK Overmolding: Benefits for High-Performance Parts

How to Specify Oil-Resistant Rubber Seal Materials for Procurement

Comparing ABS vs Nylon Plastic Connectors for Outdoor Use

FAQs

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

The plastic plug manufactured by Insert molding with stainless steel plate

The Bost custom PPO flow valve by injection molding

The Bost custom plastic handle by injection molding with high performance PPS material

The Bost custom flow meter by injection molding with PES plastic

Get in touch with Bost

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code