Send My Request

Inspection and Quality Control for Engineered Plastic Components

- Inspection and Quality Control for Engineered Plastic Components: Ensuring Reliable Performance

- Why inspection matters for engineered plastic components

- About the product: Bost’s black POM spacer and why POM matters

- Product introduction and performance claims

- Key QC goals for engineered plastic components

- What inspection must prove

- Incoming material inspection for engineered plastic components

- Raw-material verification and certificates

- In-process controls during injection molding

- Process parameters and SPC

- Final inspection: dimensional and visual checks

- Dimensional verification methods

- Mechanical, wear and functional testing

- Verifying performance, not just dimensions

- Advanced inspections: internal defects and thermal analysis

- When to use CT, X-ray and DSC

- Surface quality and appearance criteria

- Defect classification and accept/reject criteria

- Quality management systems and standards

- Certifications that support reliable supply

- Traceability, documentation and batch control

- How to ensure accountability across lots

- Comparison table: common inspection methods for engineered plastic components

- Design for inspection: tips to make inspection easier and cheaper

- Design and tooling recommendations

- Brand advantage: why choose Bost for engineered plastic components

- Bost’s strengths in producing reliable injection-molded components

- FAQ — Inspection and Quality Control for Engineered Plastic Components

- Q1: What tests should I request for a black POM spacer?

- Q2: How often should incoming POM material be tested?

- Q3: Can visual inspection alone ensure part quality?

- Q4: What standards support QC for engineered plastic components?

- Q5: How does Bost ensure wear resistance in its black POM spacer?

- Contact us / View the product

- Authoritative references

- End of article

Inspection and Quality Control for Engineered Plastic Components: Ensuring Reliable Performance

Why inspection matters for engineered plastic components

Engineered plastic components are used in applications where performance, repeatability and long service life are critical. Poorly inspected or uncontrolled parts can cause assembly failures, increased warranty claims, and safety risks. For example, a mis-sized spacer in a mechanical assembly can generate stress concentrations, misalignment, or excessive wear. That is why robust inspection and quality control (QC) processes are essential across the supply chain — from raw material receipt to final shipping. This article focuses on practical, proven QC approaches relevant to components such as Bost’s black POM spacer and other precision injection-molded parts.

About the product: Bost’s black POM spacer and why POM matters

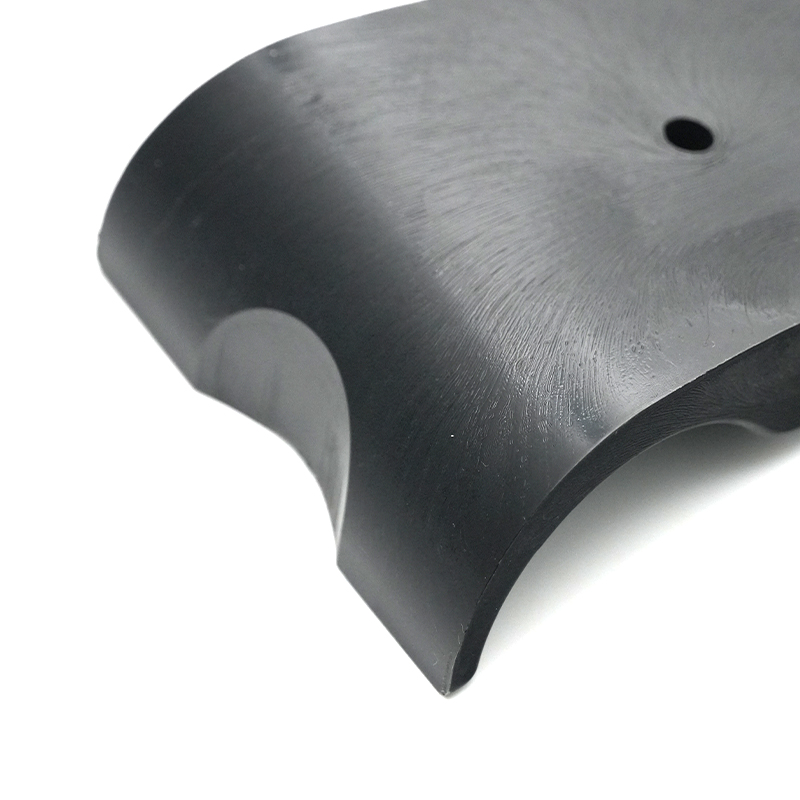

Product introduction and performance claims

Bost’s black POM spacer, injection-molded for superior wear resistance and dimensional stability, ensures precise positioning in demanding applications. Crafted for durability, this injection-molded black POM wear-resistant spacing offers reliable performance and long-lasting support. Polyoxymethylene (POM, also known as acetal) is widely chosen for spacers, bearings and precision components because of its low friction, good mechanical strength, and dimensional stability when processed correctly.

Key QC goals for engineered plastic components

What inspection must prove

Quality control should demonstrate that each delivered component meets the customer’s functional and specification-driven requirements. Primary QC goals include:

- Dimensional accuracy and geometric tolerances (critical for fit and assembly)

- Surface appearance and absence of critical defects (flash, sink marks, flow lines)

- Mechanical properties (tensile strength, impact resistance, flexural strength)

- Wear resistance and coefficient of friction for sliding parts

- Material verification and traceability (grade, color, additive package)

- Process stability and repeatability (statistical process control, SPC)

Incoming material inspection for engineered plastic components

Raw-material verification and certificates

Begin QC at the incoming raw material stage. For engineered plastic components like a black POM spacer, this includes verifying the polymer grade, color masterbatch, and any lubricants or fillers. Acceptable inspections include:

- Supplier Certificate of Analysis (CoA) review — material lot, melt flow, density

- Visual check for contamination, moisture or unusual odors

- Random sample tests — density check, melt flow indication or DSC if crystallinity needs confirmation

Maintaining material lot traceability is essential: record supplier lot numbers and link them to production lots for the finished components.

In-process controls during injection molding

Process parameters and SPC

In-process QC reduces downstream rejects and ensures the critical attributes of engineered plastic components are controlled. Recommended practices:

- Establish and record key process parameters: barrel temperatures, melt temperature, injection speed, hold pressure, cooling time, mold temperature

- Use Statistical Process Control (SPC) charts for cavity pressure, part weight and cycle time to detect drift

- Check tooling condition and wear — tool temperature, venting and gate quality affect flash and dimensional variation

- First-article inspection (FAI) or sample run to confirm dimensions and appearance before production continues

Final inspection: dimensional and visual checks

Dimensional verification methods

Dimensional accuracy is the primary acceptance criterion for spacers and positioning components. Typical dimensional inspection methods:

- Calipers and micrometers for simple dimensions

- Go/no-go gauges for high-volume checks of critical features

- Coordinate Measuring Machine (CMM) for complex geometries and GD&T checks

- Optical comparators and vision systems for small features and pattern matching

Document sampling plans (e.g., ANSI/ASQ Z1.4) and sampling frequency. For high-criticality engineered plastic components, 100% inspection of certain critical dimensions may be justified.

Mechanical, wear and functional testing

Verifying performance, not just dimensions

Dimensional compliance does not guarantee functional performance. For engineered plastic components like an injection-molded black POM wear spacer, you should perform mechanical and wear tests appropriate to the application:

- Tensile and elongation (ASTM D638) to verify base mechanical properties

- Flexural testing (ASTM D790) for stiffness

- Impact testing (ASTM D256 or ISO equivalents) if shock loading is expected

- Wear testing such as pin-on-disk (ASTM G99) or custom tribological tests to simulate sliding conditions

- Hardness (Shore D) for surface resistance to indentation

Advanced inspections: internal defects and thermal analysis

When to use CT, X-ray and DSC

Some issues are internal or microstructural and require advanced tools:

- X-ray or micro-CT scanning to detect internal voids, inclusions or short shots without destroying the part

- Differential Scanning Calorimetry (DSC) to understand crystallinity and thermal properties which influence dimensional stability

- Thermogravimetric Analysis (TGA) for additive or filler content where composition is critical

Surface quality and appearance criteria

Defect classification and accept/reject criteria

Surface defects affect function and customer perception. Create a documented classification for defects: Class 1 (critical — reject), Class 2 (major — conditionally reject), Class 3 (cosmetic — report). Typical defects for injection-molded engineered plastic components include:

- Flash or burrs that affect assembly — Class 1

- Sink marks near load paths — Class 2

- Discoloration, streaks or flow lines — Class 3 (may still be unacceptable for cosmetic applications)

Quality management systems and standards

Certifications that support reliable supply

Implementing a Quality Management System (QMS) like ISO 9001 is a baseline for consistent engineered plastic components. For automotive customers, IATF 16949 is commonly required. Other practices include Production Part Approval Process (PPAP) documentation, APQP for development, and incoming supplier approvals.

Traceability, documentation and batch control

How to ensure accountability across lots

Traceability practices to implement:

- Lot IDs for raw material, tool cavity, and production run

- Retention samples for each production lot to support failure analysis

- Digitized QC records and inspection reports tied to shipment numbers

Comparison table: common inspection methods for engineered plastic components

| Inspection Method | Purpose | Typical Tools | Recommended Use |

|---|---|---|---|

| Visual Inspection | Surface defects, flash, color | Magnifier, lighting stations, cameras | 100% or sample checks for appearance-sensitive parts |

| Dimensional Inspection | Verify tolerances and fit | Calipers, micrometers, CMM, gauges | Critical for spacers and mating components; use CMM for complex tolerances |

| Mechanical Testing | Strength, stiffness, impact resistance | Universal testers, impact testers | Periodic validation and incoming material checks |

| Wear/Tribology | Measure wear rate, friction | Pin-on-disk, custom apparatus | Necessary for moving/sliding parts like POM spacers |

| CT/X-ray | Internal defects, voids | Micro-CT or industrial X-ray | Use for complex parts or failure investigation |

| Thermal Analysis | Crystallinity, melting behavior | DSC, TGA | Material verification and process optimization |

Design for inspection: tips to make inspection easier and cheaper

Design and tooling recommendations

Design engineers can reduce QC burden and improve first-pass yield by:

- Simplifying critical dimensions and reducing unnecessary tight tolerances

- Adding inspection-friendly features or reference surfaces for quick checks

- Specifying radii and draft angles appropriate for POM to reduce sink and stress

- Designing gates and runners to reduce burn marks and flow lines in critical areas

Brand advantage: why choose Bost for engineered plastic components

Bost’s strengths in producing reliable injection-molded components

Bost combines material expertise, mold-making precision and a rigorous QC program to deliver dependable engineered plastic components. Key advantages:

- Material selection: optimized POM grades for wear resistance and dimensional stability

- Controlled injection molding processes with SPC and first-article approvals

- Comprehensive inspection labs offering dimensional, mechanical and tribological testing

- Full traceability from material lot to shipment and retention samples for each lot

That combination ensures that Bost’s black POM spacer performs reliably in demanding environments while meeting customer specifications and regulatory expectations.

FAQ — Inspection and Quality Control for Engineered Plastic Components

Q1: What tests should I request for a black POM spacer?

A: Request dimensional inspection (CMM or calibrated gauges), surface inspection (visual/optical), mechanical tests (tensile, flexural, impact), hardness (Shore D) and wear testing (pin-on-disk or application-simulating test). Also request material CoA and lot traceability.

Q2: How often should incoming POM material be tested?

A: At minimum, verify every new lot with a CoA and visual check; perform sample mechanical/thermal tests when changing supplier, grade, or if the application is critical. Many suppliers perform batch testing and can share CoAs.

Q3: Can visual inspection alone ensure part quality?

A: No. Visual inspection catches surface defects but not internal voids, dimensional drift or changes in mechanical properties. Combine visual checks with dimensional and functional tests per the part’s risk level.

Q4: What standards support QC for engineered plastic components?

A: ISO 9001 for QMS, IATF 16949 for automotive, and ASTM/ISO test methods for mechanical and thermal characterization (e.g., ASTM D638 for tensile). Use PPAP documentation for production part approvals in automotive supply chains.

Q5: How does Bost ensure wear resistance in its black POM spacer?

A: Bost selects the appropriate POM grade and optimizes molding conditions to achieve recommended crystallinity and surface finish. Wear tests and life-cycle simulations validate performance under expected loading and friction conditions.

Contact us / View the product

Once quality control systems are in place, the process comes full circle—reassessing sourcing strategy for future projects. Revisiting selecting engineered plastic components for high-volume production helps align inspection data with long-term component selection decisions.If you need engineered plastic components with verified performance, contact Bost for sample testing, PPAP documentation, or to request a quotation for Bost’s black POM spacer. Our QC team can provide test reports, material CoAs and recommendations tailored to your assembly. Visit the product page or contact sales to request samples and technical datasheets.

Authoritative references

- Polyoxymethylene (POM) — Wikipedia: https://en.wikipedia.org/wiki/Polyoxymethylene

- ISO 9001 — Quality management systems: https://www.iso.org/iso-9001-quality-management.

- IATF 16949 — Automotive QMS information: https://www.iatfglobaloversight.org/

- ASTM International — Standards and test methods: https://www.astm.org/

- Plastics Industry Association — Industry resources: https://www.plasticsindustry.org/

End of article

Certifications and Standards for UV-Resistant ABS Connectors

Cost Analysis: PEEK Overmolding vs Alternative Methods

Innovations in Custom Injection Molding: What to Expect in 2025

Engineering Plastic Cost: Price, Value and Lifecycle Analysis

FAQs

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

The plastic plug manufactured by Insert molding with stainless steel plate

The Bost custom PPO flow valve by injection molding

The Bost custom plastic handle by injection molding with high performance PPS material

The Bost custom flow meter by injection molding with PES plastic

Get in touch with Bost

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code