Send My Request

Reducing Assembly Costs with Injection-Molded POM Spacers

- Reducing Assembly Costs with Injection-Molded POM Spacers

- Why engineered plastic components deliver better value in assemblies

- Product overview: The black POM spacer made by injection molding

- How injection-molded POM spacers reduce assembly costs

- Design considerations to maximize cost savings with injection-molded black POM spacers

- Performance comparison: black POM spacer vs metal and other plastics

- Applications and illustrative cost-saving examples

- Manufacturing and quality control best practices for injection-molded POM spacers

- Sustainability and lifecycle cost advantages

- Bost’s advantages: why choose our injection-molded black POM spacer

- FAQ

- Contact sales / View product

- Authoritative references

Reducing Assembly Costs with Injection-Molded POM Spacers

Engineered plastic components are increasingly replacing metals and commodity plastics in assemblies where precise positioning, wear resistance and long-term reliability matter. The black POM spacer made by injection molding provides a compelling combination of dimensional stability and wear resistance that reduces assembly time, lowers part counts and decreases total cost of ownership. This article explains how injection-molded POM spacers work as cost-saving components, offers actionable design and manufacturing guidance, and compares performance against common alternatives. Cost savings must be balanced with performance and consistency, especially in regulated or precision-driven industries. To maintain standards, inspection and quality control for engineered plastic components outlines best practices for verifying molded POM spacer quality.

Why engineered plastic components deliver better value in assemblies

Switching to engineered plastic components such as injection-molded POM spacers yields cost benefits beyond just lower piece price. Key areas of value include:

- Lower tooling and machining requirements compared with metal parts, enabling faster production cycles.

- Integrated features (snap-fit zones, positioning tabs, press-fit surfaces) that reduce fasteners and assembly steps.

- Corrosion resistance and electrical insulation, minimizing protective coatings and secondary operations.

- Reduced weight for shipping and handling savings — particularly important in high-volume applications.

- High repeatability from injection molding, reducing inspection and rework costs.

When the objective is to optimize the total assembly cost rather than just per-part material cost, engineered plastic components like injection-molded POM spacers often provide the best return on investment.

Product overview: The black POM spacer made by injection molding

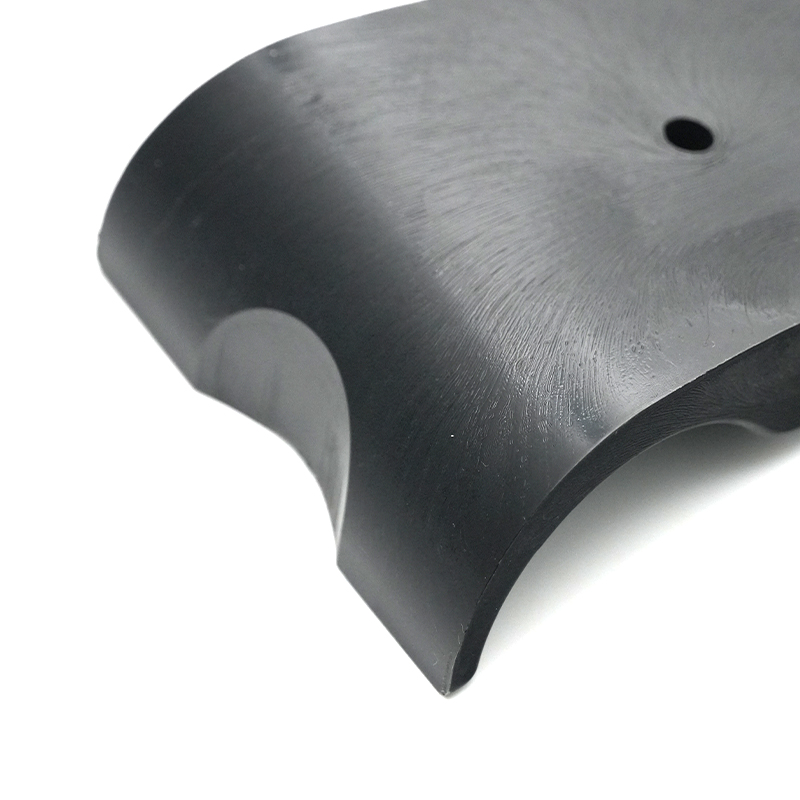

Bost’s black POM spacer, injection-molded for superior wear resistance and dimensional stability, ensures precise positioning in demanding applications. Crafted for durability, this injection-molded black POM wear-resistant spacing offers reliable performance and long-lasting support. Typical benefits of this product include tight dimensional tolerances, low friction sliding surfaces, and consistent performance across production lots — making it a practical choice for assemblies in automotive, appliance, electronics and industrial equipment.

How injection-molded POM spacers reduce assembly costs

There are several practical mechanisms through which the black POM spacer lowers assembly costs:

- Fewer parts and reduced fasteners: By designing spacers with integrated alignment features and snap-fit geometry, you can eliminate separate shims, washers or additional fasteners. This translates to shorter assembly cycles and fewer steps on the line.

- Faster and more consistent placement: Injection-molded components arrive ready to install with consistent dimensions and surface finish. Reduced variability lowers time spent on fitment adjustments and rejects.

- Lower secondary operations: POM’s natural properties frequently eliminate plating, painting or lubrication steps required for metal alternatives.

- Decreased maintenance and warranty cost: Because of POM’s wear resistance and dimensional stability, parts retain required clearances and alignment longer, reducing field failures and associated service calls.

- Handling and ergonomics: Lightweight plastic parts are easier and safer for operators to handle in high-volume assembly, improving line throughput and reducing injury risk.

Design considerations to maximize cost savings with injection-molded black POM spacers

To gain the full cost-saving effects of engineered plastic components, design for injection molding and assembly. Key considerations include:

- Design for manufacturability (DFM): Keep wall thickness uniform to avoid sink marks and warpage. Use ribs for stiffness instead of thick sections.

- Tolerances and fits: Specify tolerances achievable by injection molding (typically ±0.1–0.3 mm for many features depending on size). Where critical, use post-molding machining or controlled insert-molding strategies.

- Integration of features: Incorporate alignment keys, snap-fit latches or stacking aids directly into the spacer geometry to remove fasteners or assembly aids.

- Surface finish and lubrication: POM has low friction; in applications with sliding contact, a smooth finish from the mold and appropriate resin grade reduce break-in wear and friction-related noise.

- Thermal and environmental factors: Account for operating temperature and chemical exposure. POM performs well in many environments but specify grades or protective measures if exposure to strong acids, oxidizers or extreme temperatures is expected.

- Tooling considerations: Use hardened steel molds for long production life and consistent part quality. Plan gate locations for balanced filling and minimal gate vestige in functional areas.

Performance comparison: black POM spacer vs metal and other plastics

Below is a compact comparison of typical properties important to assembly engineers. Values are representative ranges and relative ratings; consult material datasheets for application-specific numbers.

| Characteristic | Injection-molded black POM spacer | Steel spacer | Nylon (PA) spacer |

|---|---|---|---|

| Dimensional stability | High (low creep, good machining tolerance) | Very high (requires corrosion protection) | Medium (higher moisture absorption, more dimensional change) |

| Wear resistance | High (low friction, good sliding wear) | High (hardness-dependent) | Medium (can wear faster under sliding loads) |

| Weight | Low | High | Low–Medium |

| Corrosion resistance | Excellent | Poor (needs plating/painting) | Good |

| Typical temperature range | -40 to +100°C continuous (depends on grade) | -40 to +300°C (depending on alloy) | -40 to +80°C (varies with type and moisture) |

| Relative cost per unit (high volume) | Low–Medium | Medium–High | Low |

Interpretation: For many positioning and wear-related spacer uses, the black POM spacer provides the best balance of dimensional stability, wear resistance and low lifecycle costs, especially when environmental protection or reduced weight is important.

Applications and illustrative cost-saving examples

Common applications where Bost’s injection-molded black POM spacer reduces total assembly cost include:

- Automotive interior mounting and trim positioning

- Household appliances (washers, dryers, refrigerators)

- Consumer electronics and enclosures

- Industrial equipment where vibration damping and precision spacing are needed

Illustrative example (conservative): Replacing a stamped metal spacer plus two washers and one screw with a single injection-molded black POM spacer with an integrated snap-fit feature saved 3–5 assembly seconds per part on a high-speed line. At 5,000 units per day, that reduction can translate into one less operator or a capacity increase without new hires — recovering tooling investment in months.

Manufacturing and quality control best practices for injection-molded POM spacers

To ensure consistent cost and quality benefits, follow these manufacturing best practices:

- Material drying: POM is generally less hygroscopic than nylon but follow supplier recommendations for drying and storage to maximize dimensional consistency.

- Process control: Maintain consistent melt temperature and injection speed to avoid flash and sink marks. Use well-balanced runners and appropriate venting in the mold.

- Annealing: For critical dimensions, consider post-mold annealing to relieve internal stresses and improve dimensional stability.

- Inspection: Use statistical process control (SPC) and sample inspection with calipers or CMM for critical spacing features. Track wear tests for sliding contacts.

- Traceability: Lot tracking for resin and process parameters helps resolve field issues quickly and improves E-E-A-T by documenting material provenance.

Sustainability and lifecycle cost advantages

Engineered plastic components can reduce the environmental footprint of products in multiple ways:

- Lower part count and fewer fasteners reduce materials used across the assembly.

- Reduction in weight decreases transportation energy per product.

- Longer service life and lower maintenance can reduce lifecycle environmental impact.

- Some POM grades are recyclable; choose recycled-content or reclaim-friendly manufacturing routes when applicable.

When assessing sustainability, use lifecycle cost models that include energy for production, transportation, maintenance and end-of-life handling to make an informed substitution decision.

Bost’s advantages: why choose our injection-molded black POM spacer

Bost’s black POM spacer made by injection molding combines engineered design, material selection and manufacturing discipline to deliver measurable assembly cost reductions:

- Consistent dimensional tolerances that reduce line rework and assembly time.

- High wear resistance and low friction for longer service life in sliding and rotating interfaces.

- Design-for-assembly expertise to convert multi-piece metal solutions into single plastic parts, cutting part count and labor.

- Quality systems and traceability to ensure reproducible performance at volume.

- Technical support to help you optimize designs for injection molding and assembly performance.

FAQ

Q: What is POM and why is it suitable for spacers?

A: Polyoxymethylene (POM), also known as acetal or Delrin in commercial form, is an engineering thermoplastic with high stiffness, good dimensional stability, low friction and excellent wear resistance. These properties make it ideal for spacers that require consistent positioning, sliding contact or long-term stability.

Q: Can the black POM spacer operate in high-temperature environments?

A: Standard POM grades typically perform well in continuous operation up to about 80–100°C. For higher-temperature applications, select a high-temperature POM grade or consider alternate materials. Always validate part performance under your specific thermal profile.

Q: How does moisture affect POM spacers?

A: POM has relatively low moisture uptake compared with polyamides (nylon), so dimensional changes due to humidity are smaller. Still, allow for any expected environmental variation in critical tolerance budgeting.

Q: Are black POM spacers injection-moldable at high volumes?

A: Yes. Injection molding is well suited to high-volume production of POM components. Properly designed molds and process controls enable tight tolerances and consistent quality over large production runs.

Q: Can you integrate snap-fits or other assembly features into a POM spacer?

A: Absolutely. One of the principal advantages of engineered plastic components is the ability to integrate features such as snap-fits, tabs, and locating bosses directly into the spacer to reduce part count and assembly labor.

Contact sales / View product

To evaluate Bost’s black POM spacer for your application or request samples and drawings, contact our technical sales team at sales@bost.com or visit our product page at 'https://www.bost.com/products/black-pom-spacer' to request a quote and CAD files.

Authoritative references

Choosing Materials for Insert Injection Molding: Practical Guide for Engineers

Cost Analysis: Insert Injection Molding vs Assembly — Practical Guide for Engineering Plastics

Plastic Bushing Materials Explained: Why Choose PE?

Sustainable Practices in Insert Injection Molding: A Practical Guide for Manufacturers

FAQs

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

The plastic plug manufactured by Insert molding with stainless steel plate

The Bost custom PPO flow valve by injection molding

The Bost custom plastic handle by injection molding with high performance PPS material

The Bost custom flow meter by injection molding with PES plastic

Get in touch with Bost

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code