Send My Request

Engineering Plastics vs. Commodity Plastics: 7 Vital Differences for High-Stress Applications (2026 Guide)

A comprehensive 2026 guide comparing engineering plastics and commodity plastics. Learn the 7 critical differences in heat resistance, strength, and cost to prevent material failure in high-stress applications like automotive and aerospace.

- Quick Summary: The Critical Distinction

- At a Glance: Key Differences

- What Are Engineering Plastics?

- Difference #1: Thermal Stability & Heat Resistance

- Difference #2: Mechanical Strength & Load Bearing Capacity

- Difference #3: Dimensional Stability & Creep Resistance

- Difference #4: Chemical & Environmental Resistance

- Difference #5: Machinability & Processing Precision

- Difference #6: Impact Resistance & Toughness

- Difference #7: Cost-to-Performance Ratio

- Expert Tips: Preventing Material Failure

- Future Trends: Engineering Plastics in 2026 and Beyond

- Conclusion

- Frequently Asked Questions (FAQ)

- What is the main difference between commodity and engineering plastics?

- What are 3 examples of engineering plastics?

- Can engineering plastics replace metal?

- Why are engineering plastics more expensive?

- Is PVC an engineering plastic?

Quick Summary: The Critical Distinction

For engineers and procurement specialists, the choice between engineering plastics and commodity plastics often determines product success or failure. While commodity plastics dominate in volume for disposable items, engineering plastics are the backbone of durable, high-performance manufacturing.

At a Glance: Key Differences

|

Feature |

Commodity Plastics (PE, PP, PS) |

Engineering Plastics (PC, PA, PEEK) |

|

Primary Focus |

Low cost, high volume, ease of processing |

High performance, durability, reliability |

|

Thermal Limit |

Typically < 100°C (212°F) |

Often > 150°C (300°F) to 250°C+ |

|

Mech. Strength |

Low to Moderate |

High tensile strength & stiffness |

|

Cost |

Low raw material cost |

Higher cost, better lifecycle value |

|

Typical Use |

Packaging, toys, disposable cups |

Automotive gears, aerospace, medical |

What Are Engineering Plastics?

Engineering plastics are a group of plastic materials specifically designed to possess better mechanical and thermal properties than widely used commodity plastics.

Unlike standard plastics used for packaging, engineering plastics are formulated to withstand high mechanical loads, extreme temperatures, and harsh chemical environments. They bridge the gap between general-purpose plastics and metals, often replacing aluminum or steel to reduce weight without sacrificing structural integrity.

To dive deeper into specific formulations, you might explore What Is Special Engineering Plastics? for a detailed breakdown of high-performance grades.

Common Examples:

· Polycarbonate (PC): Impact-resistant (e.g., safety goggles).

· Polyamides (Nylon/PA): Wear-resistant (e.g., gears).

· Acrylonitrile Butadiene Styrene (ABS): Rigid and tough (e.g., housings).

Difference #1: Thermal Stability & Heat Resistance

The most defining difference is that engineering plastics can maintain their mechanical properties at continuous service temperatures above 100°C, whereas commodity plastics typically degrade or melt.

In high-stress environments, heat is the enemy. Commodity plastics like Polyethylene (PE) or Polystyrene (PS) have low melting points and low Heat Deflection Temperatures (HDT). They will soften and lose shape if exposed to the heat generated by friction or engines.

Why It Matters:

· Engine Components: A plastic engine cover must withstand temperatures exceeding 120°C while resisting oil and vibration. Only an engineering plastic like glass-filled Nylon (PA66) or PEEK can survive this environment.

· Fire Safety: Many engineering grades are inherently flame-retardant (UL94 V-0 rated), making them essential for electronics.

Difference #2: Mechanical Strength & Load Bearing Capacity

Engineering plastics offer superior tensile strength and modulus (stiffness), allowing them to bear structural loads that would cause commodity plastics to buckle or snap.

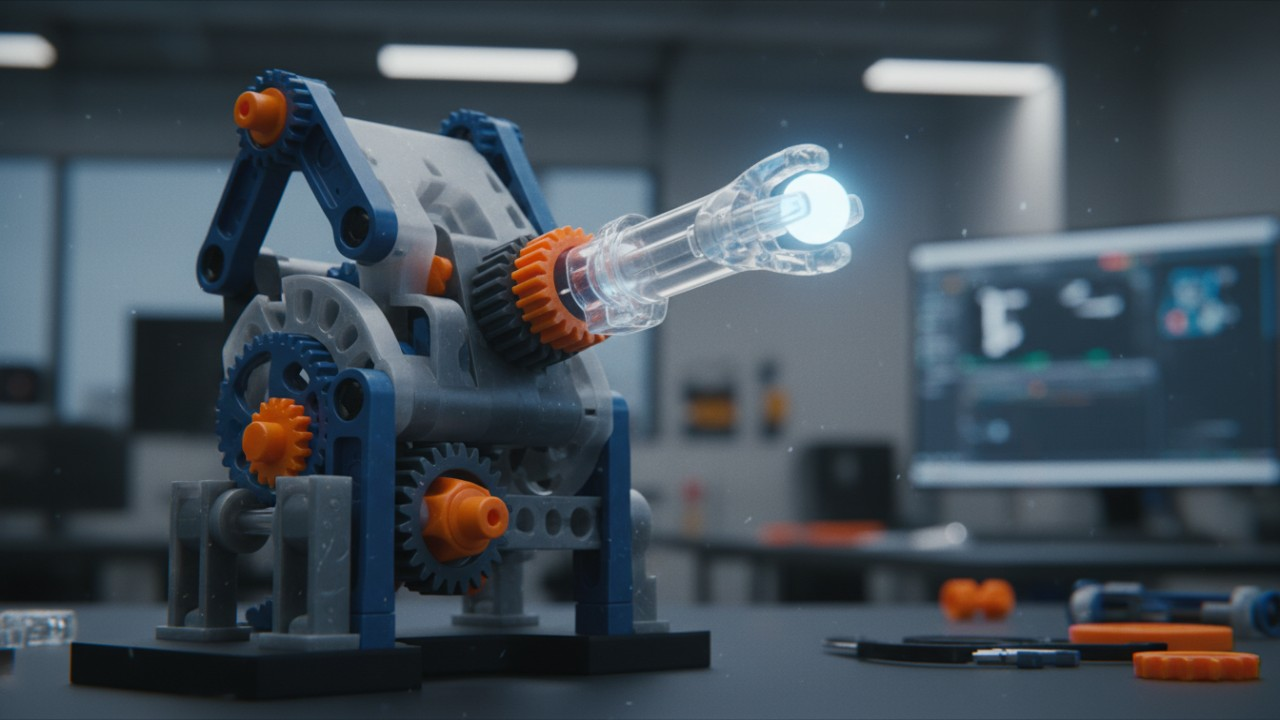

While a commodity plastic cup is designed to hold liquid, an engineered plastic gear is designed to transmit torque. The molecular structure of engineering materials is often reinforced with fibers (glass or carbon) to enhance stiffness.

Performance Metrics:

· Tensile Strength: Engineering grades can exceed 100 MPa, compared to ~20-30 MPa for standard PE.

· Fatigue Resistance: Materials like Polyacetal (POM) can endure millions of cyclic loads (bending back and forth) without failure, a critical requirement for springs and snap-fits.

Difference #3: Dimensional Stability & Creep Resistance

Creep is the tendency of a solid material to slowly deform permanently under the influence of mechanical stresses; engineering plastics are formulated to resist this "cold flow" significantly better than commodity types.

If you place a heavy weight on a block of commodity plastic (like HDPE), it will slowly squash over weeks or months, even at room temperature. This makes it unsuitable for precision parts where tight tolerances are mandatory.

Key Applications:

· Precision Gears: Must retain exact tooth shape to prevent slippage.

· Bearings and Seals: Must maintain a tight fit to prevent leakage.

· Structural Housings: Must not warp under the weight of internal components.

Difference #4: Chemical & Environmental Resistance

Engineering plastics provide robust resistance to harsh industrial chemicals, fuels, and solvents, whereas commodity plastics are often vulnerable to stress cracking and degradation.

While commodity plastics like Polypropylene are chemically resistant to acids (which is why they are used for bleach bottles), they often fail when exposed to hydrocarbons, oils, or UV radiation. Engineering plastic materials are often selected specifically for their ability to survive where others dissolve.

Real-World Scenarios:

· Automotive Fluids: A plastic cover for engine components must resist brake fluid, gasoline, and oil.

· Sterilization: Medical devices made from PSU (Polysulfone) can withstand repeated autoclaving (steam sterilization), whereas commodity plastics would melt or warp.

Difference #5: Machinability & Processing Precision

Engineering plastics are manufactured to hold much tighter tolerances during machining and molding, ensuring consistent reproducibility for complex geometries.

When manufacturers process high-performance engineering plastic granules, they rely on predictable shrinkage rates. Commodity plastics often have high or variable shrinkage, making it difficult to mold precision parts with complex features like thin walls or threads.

Manufacturing Advantages:

· CNC Machining: Engineering grades produce clean chips and smooth surface finishes, unlike soft commodity plastics that may melt or "gum up" the tool.

· Complex Modeling: Even for niche uses like plastic models of engines used in education or prototyping, engineering resins (like ABS or SLA resins) are preferred over commodity options for their ability to capture fine detail without warping.

Difference #6: Impact Resistance & Toughness

Toughness in engineering plastics is defined by the ability to absorb energy and deform plastically without fracturing, unlike brittle commodity plastics that shatter under impact.

Drop a Polystyrene (commodity) casing, and it cracks. Drop a Polycarbonate (engineering) casing, and it bounces. This "ductility" is vital for safety equipment and consumer electronics.

Comparison:

· Polycarbonate (PC): Virtually unbreakable; used in bulletproof glass and riot shields.

· Acrylic (PMMA): Often considered a bridge material, but standard grades are brittle compared to true engineering plastics.

· Nylon (PA): Becomes incredibly tough after absorbing a small amount of moisture (conditioning).

Difference #7: Cost-to-Performance Ratio

While engineering plastics have a higher upfront raw material cost (per kg), they offer a lower Total Lifecycle Cost by reducing part weight, eliminating secondary operations, and preventing premature failure.

Commodity plastics are cheap—often costing less than $1.50 per kg. Engineering plastics can range from $3.00 to over $100.00 per kg for specialized grades like PEEK. However, looking at the price tag alone is a mistake.

The Value Equation:

1. Durability: One PEEK gear can outlast 100 cheap plastic gears, saving on maintenance and downtime.

2. Lightweighting: Replacing metal with engine cover plastic reduces vehicle weight, improving fuel economy and lowering emissions.

3. Integration: A single molded engineered plastic part can replace an assembly of five metal parts, reducing assembly labor costs.

Expert Tips: Preventing Material Failure

The most common cause of plastic part failure is not the material itself, but selecting the wrong material for the operating environment.

· Don't Trust "Room Temperature" Data: Datasheets often list properties at 23°C. Always check performance curves at your application's maximum operating temperature.

· Watch for Hydrolysis: Some polyesters (like PBT) can degrade in hot water. For wet, hot environments, ensure you select hydrolysis-resistant grades.

· Consult Specialists: Using generic "Nylon" isn't enough. You must specify the fill (glass/carbon) and additives (UV stabilizers). Specialized knowledge is key to Unlocking the Core Value of Special Engineering Plastics in your production line.

Future Trends: Engineering Plastics in 2026 and Beyond

The market for engineering plastics is shifting toward bio-based formulations and AI-driven material discovery to meet aggressive sustainability goals without compromising performance.

According to recent market reports, the global engineering plastics market was valued at approximately $120.5 billion in 2024 and is projected to grow at a CAGR of roughly 6% through 2032. The drive for electric vehicles (EVs) is a primary accelerator.

2026 Trends to Watch:

1. EV Lightweighting: As battery weight remains a challenge, plastic engineering is focused on replacing even more metal structural components in chassis and battery housings.

2. Circular Economy: Major chemical companies are launching "advanced recycling" grades of PC and PA that offer virgin-quality performance from recycled waste.

3. Smart Polymers: Development of conductive plastics that can dissipate heat or provide EMI shielding for 5G electronics.

Conclusion

Understanding the distinction between engineering plastics and commodity plastics is fundamental to modern product design. While commodity plastics serve the world of disposables well, engineering plastics are the invisible heroes of the industrial world—keeping our cars running, our electronics safe, and our medical devices sterile. By prioritizing thermal stability, mechanical strength, and lifecycle value, manufacturers can ensure their products stand up to the high-stress demands of 2026 and beyond.

Frequently Asked Questions (FAQ)

What is the main difference between commodity and engineering plastics?

The primary difference is performance. Engineering plastics have superior mechanical and thermal properties (like heat resistance >100°C) compared to commodity plastics, which are used for mass-produced, low-stress items.

What are 3 examples of engineering plastics?

Three common examples are Polycarbonate (PC) (known for impact strength), Polyamide (Nylon/PA) (known for wear resistance), and Polyoxymethylene (Acetal/POM) (known for low friction).

Can engineering plastics replace metal?

Yes, they frequently replace metals like aluminum and steel to reduce weight and prevent corrosion. This is common in automotive applications, such as a plastic engine cover, to improve fuel efficiency.

Why are engineering plastics more expensive?

They require more complex manufacturing processes and specialized raw materials. However, their durability often results in lower total lifecycle costs compared to frequent replacements of cheaper materials.

Is PVC an engineering plastic?

Generally, PVC is considered a commodity plastic due to its high-volume use in construction (pipes). However, certain rigid, modified grades can perform well enough to bridge the gap into some engineering applications.

Recommended for you

FAQ

FAQs

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

You may also like

The plastic plug manufactured by Insert molding with stainless steel plate

The Bost custom PPO flow valve by injection molding

The Bost custom plastic handle by injection molding with high performance PPS material

The Bost custom flow meter by injection molding with PES plastic

Leave a Message

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

© 2026 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code