Send My Request

Ultimate Guide to Plastic Bushings 2026: Selection, Types & Performance

A comprehensive guide for engineers and designers on selecting, installing, and maintaining plastic bushings. Covers material properties, PV values, failure modes, and future trends.

- Introduction to Plastic Bushings: The Modern Solution for Motion

- Unveiling the Advantages: Why Plastic Bushings Excel in Modern Engineering

- Self-Lubrication and Low Friction

- Superior Corrosion and Chemical Resistance

- Lightweight and Noise Dampening

- Key Plastic Materials for Bushings: A Deep Dive into Performance

- Plastic Bushings vs. Metal Bushings: A Comprehensive Head-to-Head Comparison

- Versatile Applications of Plastic Bushings Across Diverse Industries

- The Ultimate Selection Guide: Choosing the Right Plastic Bushing

- Limitations and Critical Design Considerations

- Installation, Maintenance, and Troubleshooting

- The Future of Plastic Bushings: Innovations and Sustainability

- Conclusion: Empowering Your Designs

- Frequently Asked Questions

- What is the primary function of a plastic bushing?

- How do plastic bushings differ from metal bushings?

- What are the most common plastic materials used for bushings?

- Are plastic bushings always self-lubricating?

- In what industries are plastic bushings most commonly used?

- What factors should I consider when selecting a plastic bushing?

- Can plastic bushings withstand high temperatures?

- Do plastic bushings require any maintenance?

- References

Introduction to Plastic Bushings: The Modern Solution for Motion

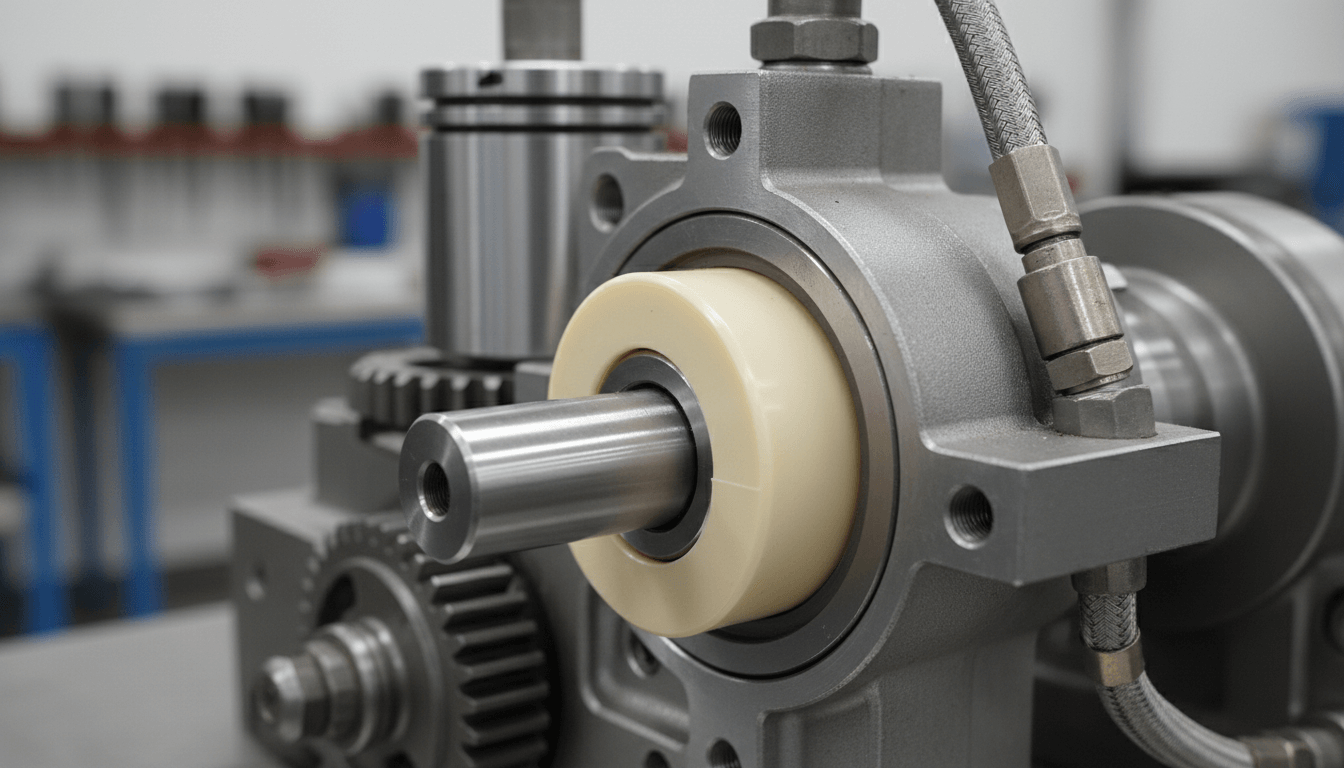

In the evolving landscape of mechanical engineering, plastic bushings—also known as plain bearings—have transitioned from niche alternatives to fundamental components in high-performance assemblies. A plastic bushing serves as a replaceable interface between a moving shaft and its housing, designed to minimize friction, support loads, and prevent metal-on-metal wear. Unlike their traditional bronze or steel counterparts, modern plastic bearing materials offer a unique combination of self-lubrication, corrosion resistance, and vibration dampening.

The adoption of plastic bushings has surged across industries ranging from automotive to food processing. As engineering demands for lighter, quieter, and maintenance-free systems increase, the versatility of a bushing plastic solution becomes undeniable. Whether you are sourcing a standard 1 2 plastic bushing for a conveyor system or a specialized plastic bushing sleeve for an aerospace application, understanding the nuances of these polymer components is essential for modern design.

Unveiling the Advantages: Why Plastic Bushings Excel in Modern Engineering

Engineers are increasingly specifying plastic bush solutions over metal for several compelling reasons. The shift is driven not just by cost, but by superior performance in specific operating conditions.

Self-Lubrication and Low Friction

One of the most significant advantages is the tribological performance. As noted by Emerson Bearing, many plastic bushings are self-lubricating, containing solid lubricants (like PTFE or graphite) embedded within the polymer matrix. This eliminates the need for external grease, reducing maintenance intervals and preventing contamination—a critical factor in medical and food packaging sectors.

Superior Corrosion and Chemical Resistance

Metals oxidize and corrode, especially in saline or acidic environments. Plastic bushings inherently resist rust and a wide spectrum of chemicals. For engineers designing equipment for washdown environments, the Chemical Resistance of PE Plastic Bushes is a vital consideration, often outperforming metal bearings that require expensive sealing or plating.

Lightweight and Noise Dampening

Plastics are significantly lighter than metals, contributing to overall system efficiency and fuel economy in automotive applications. Furthermore, the viscoelastic nature of polymers allows them to absorb vibration and dampen noise, addressing the "stick-slip" squeak often associated with metal interfaces.

Key Plastic Materials for Bushings: A Deep Dive into Performance

Selecting the right plastic bearing materials is the cornerstone of bushing performance. Each polymer offers a distinct balance of strength, thermal stability, and friction.

· Nylon (Polyamide): A workhorse material known for toughness and high load-bearing capacity. It is cost-effective but can absorb moisture, which may affect dimensional stability.

· Acetal (POM): Offers a lower coefficient of friction than Nylon and negligible moisture absorption, making it ideal for wet environments. It is a preferred choice for precision parts.

· UHMW-PE: Ultra-High Molecular Weight Polyethylene is prized for its extreme impact resistance and low friction. It is often used in chutes and wear strips.

· PTFE (Teflon): Provides the widest temperature range and almost universal chemical resistance. However, it is softer and prone to creep under high loads unless reinforced.

· PEEK: The gold standard for high-performance applications. PEEK withstands extreme temperatures (up to 480°F/250°C) and high loads, as highlighted by Advanced EMC Technologies, though it comes at a higher premium.

For a detailed analysis, our technical guide naturally compares PE Plastic Bushes with Nylon and PTFE for use as plastic bushings, helping you weigh cost against performance metrics.

Plastic Bushings vs. Metal Bushings: A Comprehensive Head-to-Head Comparison

When deciding between a plastic bushing and a metal one, the decision often comes down to the "PV Value" (Pressure x Velocity) and environmental factors.

· Load Capacity: Metal bushings (e.g., bronze) generally handle higher static loads. However, fiber-reinforced plastics are narrowing this gap.

· Maintenance: Metal bushings almost always require periodic lubrication. Plastic options are typically "fit and forget."

· Shaft Wear: A plastic bush is non-galling and will not score a metal shaft even if the bearing fails. In contrast, a seized metal bearing can destroy the shaft, leading to catastrophic equipment failure.

· Cost: While high-end polymers like PEEK can be expensive, standard materials like Nylon or Acetal usually offer a lower total cost of ownership when factoring in maintenance and lifespan.

Versatile Applications of Plastic Bushings Across Diverse Industries

The utility of these components spans virtually every sector:

· Automotive: Suspension control arms, pedal assemblies, and steering columns utilize plastic bushings to reduce weight and NVH (Noise, Vibration, Harshness).

· Electrical Infrastructure: The plastic conduit bushing is a safety-critical component. According to Revco Electric, these bushings screw onto the ends of threaded conduits to protect wire insulation from sharp metal edges, ensuring compliance with NEC standards.

· Industrial Machinery: From a tiny split plastic bushing used in retrofitting easy-to-install wear guides, to large plastic bushing sleeve inserts in heavy agricultural equipment.

· Sizing Variety: Applications range from miniature precision instruments to heavy-duty rollers requiring substantial sizes like a 1 1 2 plastic bushing, 2 plastic bushing, or even a 2 1 2 plastic bushing. Standard imperial sizes such as 1 2 plastic bushing and 3 4 plastic bushing are readily available for general mechanical use.

The Ultimate Selection Guide: Choosing the Right Plastic Bushing

To select the optimal plastic bushing, engineers should follow a structured approach:

1. Calculate PV Value: Determine the Pressure (P) and Velocity (V) of your application. Ensure the chosen material's limiting PV value exceeds your operating numbers.

2. Define Environmental Factors: Is the environment wet, dusty, or chemically aggressive? For instance, a plastic bushing electrical application might prioritize dielectric strength over load capacity.

3. Check Dimensions: Verify the shaft diameter and housing bore. Whether you need a small plastic bushing for conduit or a large mechanical bearing, precision in tolerance is key.

4. Consider Thermal Expansion: Plastics expand more than metals. As noted by Curbell Plastics, design clearances must account for thermal growth to prevent seizing.

5. Evaluate Installation Style: Does the assembly require a press-fit plain bushing, a flanged bushing for axial loads, or a split plastic bushing for installation without disassembly?

Limitations and Critical Design Considerations

While versatile, plastic bushings are not a universal cure-all. Engineers must be aware of limitations to prevent failure.

· Creep and Cold Flow: Under sustained heavy loads, plastics can deform over time, a phenomenon known as creep. The Madison Group highlights that this is a primary failure mode in unreinforced polymers.

· Thermal Dissipation: Plastics are insulators. Unlike metal, they do not conduct heat away from the friction interface effectively, which can lead to melting if PV limits are exceeded.

· Moisture Absorption: Nylon can swell in humid environments, potentially causing the bushing to bind on the shaft. In such cases, Acetal or PEEK may be superior choices.

Installation, Maintenance, and Troubleshooting

Proper installation is critical for longevity. Most plastic bushings are designed to be press-fitted into a housing, which compresses the inner diameter to the correct tolerance.

· Best Practices: Use a mechanical press rather than a hammer to avoid fracturing the material. Ensure the housing bore is chamfered to ease insertion.

· Maintenance: While they are self-lubricating, periodic visual inspection for excessive wear or debris accumulation is recommended.

· Troubleshooting: If a bushing fails prematurely, check for misalignment or excessive heat buildup. The presence of melted material indicates the PV limit was exceeded.

The Future of Plastic Bushings: Innovations and Sustainability

Looking toward 2026 and beyond, the industry is seeing a rise in "smart" bushings embedded with wear sensors to predict failure before it happens. Additionally, sustainability is driving the development of bio-based high-performance polymers, reducing the carbon footprint of plastic bearing materials without compromising on durability.

Conclusion: Empowering Your Designs

Mastering the use of plastic bushings involves more than just swapping out metal parts; it requires a holistic understanding of materials, tribology, and operating environments. By leveraging the advanced properties of modern polymers, engineers can create systems that are more efficient, durable, and cost-effective.

Frequently Asked Questions

What is the primary function of a plastic bushing?

Plastic bushings act as plain bearings to support moving loads, reduce friction between mechanical parts, and prevent wear on shafts and housings.

How do plastic bushings differ from metal bushings?

Plastic bushings are typically self-lubricating, corrosion-resistant, and lighter than metal bushings. However, metal bushings generally support higher static loads and conduct heat better.

What are the most common plastic materials used for bushings?

The most common materials include Nylon, Acetal (POM), PTFE (Teflon), UHMW-PE, and PEEK, each selected based on load, speed, and temperature requirements.

Are plastic bushings always self-lubricating?

Most engineering plastic bushings are formulated with internal lubricants like PTFE, graphite, or silicone, making them self-lubricating. However, some basic plastics may still benefit from initial lubrication.

In what industries are plastic bushings most commonly used?

They are ubiquitous in automotive manufacturing, food and beverage processing, medical device production, agricultural machinery, and electrical infrastructure (e.g., plastic conduit bushing).

What factors should I consider when selecting a plastic bushing?

You must consider the Load (Pressure), Speed (Velocity), operating temperature, chemical exposure, and the mating shaft material.

Can plastic bushings withstand high temperatures?

Yes, high-performance polymers like PEEK and PTFE can operate continuously at temperatures exceeding 400°F (200°C), whereas standard Nylon is limited to lower ranges.

Do plastic bushings require any maintenance?

They require significantly less maintenance than metal bearings. While often maintenance-free, they should be inspected periodically for wear or misalignment.

References

· Pexco: Advantages of High-Performance Polymer Bearings and Bushings

· Curbell Plastics: Nylon vs Acetal Material Matchup

· Advanced EMC Technologies: The Five Most Popular Materials for Polymer Bushings

· The Madison Group: Understanding Creep Failure of Plastics

Recommended for you

FAQ

FAQs

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

You may also like

The plastic plug manufactured by Insert molding with stainless steel plate

The Bost custom PPO flow valve by injection molding

The Bost custom plastic handle by injection molding with high performance PPS material

The Bost custom flow meter by injection molding with PES plastic

Leave a Message

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code