Send My Request

Bost — Premium Engineering Plastics & Custom Injection Molding

Bost — High Quality Engineering Plastics for Demanding Applications

Product Overview

Bost specialises in high-tech engineering plastics and special engineering plastics, supplying sheets, rods and molded components engineered for extreme performance. Our portfolio includes ultra-high anti-scar, super corrosion resistance, super fatigue durability, ultra abrasion resistance and high-temperature transparent materials designed to meet rigorous industrial demands.

Materials & Special Properties

Bost offers materials enhanced for specific functions: enhanced toughening, flame retardancy, impact absorption, conductivity, and thermal management. Each grade is formulated and processed to maintain mechanical integrity while delivering targeted properties for long-term reliability in harsh environments.

Custom Manufacturing & China Custom Plastic Injection Molding

Our china custom plastic injection molding capability enables rapid prototyping and volume production with tight tolerances. From mold design and fabrication to precision injection, we provide full-service customization—optimising material selection, fiber or filler integration, and post-processing to achieve the exact functional and aesthetic requirements of your product.

R&D, Tooling & Production Excellence

Bost’s high-level plastics modification R&D team works closely with an experienced tooling and mechanical processing group. We provide integrated services including mold design, mold manufacturing and machining to ensure every component meets performance specifications and manufacturing efficiency targets.

Applications & Industry Use Cases

Our engineered plastics are widely used in steel-plastic composites, plastic-rubber combinations, electrical insulating parts, thermal conductive components, wear parts and high-temperature transparent covers. Industries served include automotive, energy, electronics, machinery and chemical processing.

Why Choose Bost

Choosing Bost means partnering with a green-energy oriented, innovative manufacturer committed to quality and customer satisfaction. We combine advanced material science, precision manufacturing and responsive service to deliver durable, high-performance plastic solutions on time and within budget.

Contact & Next Steps

For inquiries about custom formulations, tooling or china custom plastic injection molding projects, contact Bost’s technical team. Let us develop tailored engineering plastics that solve your toughest application challenges.

china custom plastic injection molding Display

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

What is the delivery lead time? Do you offer global logistics?

Standard products: 5–15 working days; custom modifications: 2–4 weeks. We support global air/sea freight and provide export customs clearance documents (including REACH/UL certifications).

The Bost custom PPO flow valve by injection molding

The Bost custom PPO flow valve by injection molding

The Bost custom plastic handle by injection molding with high performance PPS material

The Bost custom plastic handle by injection molding with high performance PPS material

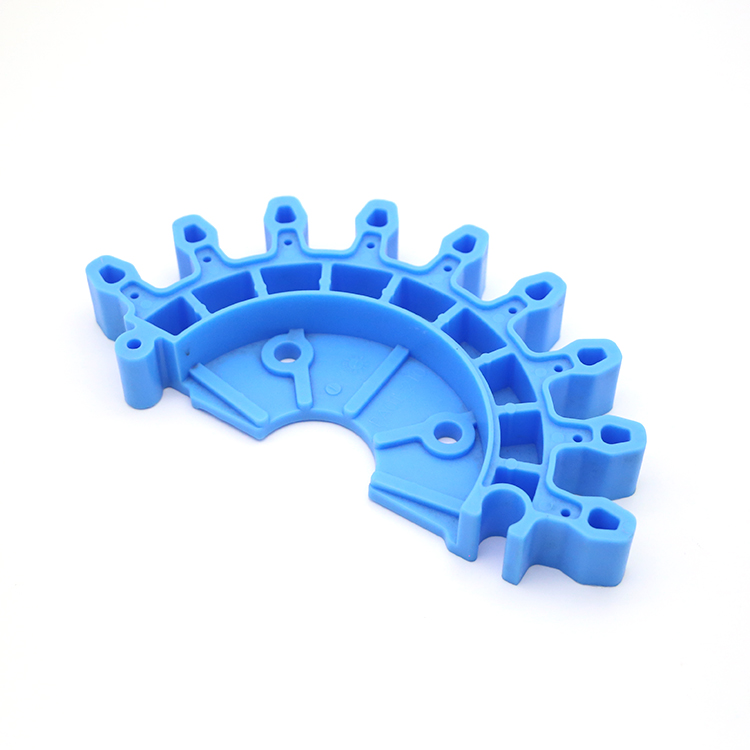

The Bost custom flow meter by injection molding with PES plastic

The Bost custom flow meter by injection molding with PES plastic

The plastic plug manufactured by Insert molding with stainless steel plate

The plastic plug manufactured by Insert molding with stainless steel plate

The Bost custom PPO flow valve by injection molding

The Bost custom PPO flow valve by injection molding

The Bost custom plastic handle by injection molding with high performance PPS material

The Bost custom plastic handle by injection molding with high performance PPS material

The Bost custom flow meter by injection molding with PES plastic

The Bost custom flow meter by injection molding with PES plasticGet in touch with Bost

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code