Send My Request

Bost Custom Worm Gears — Precision Engineering Plastics Solutions

Bost Custom Worm Gears – Precision Engineering Plastics

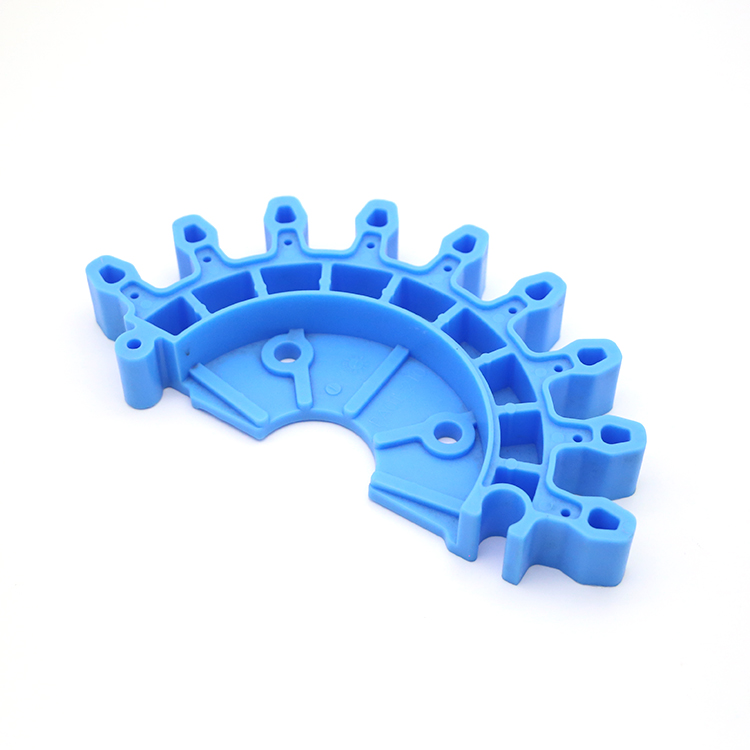

Precision Custom Worm Gears

Precision Custom Worm Gears from Bost are engineered for smooth motion, high load capacity, and long service life. Bost's custom worm gears combine optimized geometry with proprietary modified engineering plastics to reduce friction, eliminate lubrication dependency in specific applications, and ensure consistent transmission accuracy across varied speeds and loads.

Advanced Materials & Performance

Advanced Materials & Performance describe how Bost leverages ultra-high anti-scar, super corrosion-resistant, and high-temperature transparent polymers to meet unique performance targets. Our material science team enhances toughness, flame retardancy, thermal conductivity, and wear resistance so your custom worm gears perform in corrosive, high-temperature, and high-wear environments.

Applications & Industries

Applications & Industries for Bost custom worm gears span robotics, renewable energy equipment, industrial conveyors, medical devices, and automotive assemblies. These custom worm gears provide quiet operation, backlash control, and superior fatigue life—ideal where silence, reliability, and compact gear reduction are critical.

Why Choose Bost

Why Choose Bost is simple: decades of engineering plastics expertise, in-house mold design, advanced modification R&D, and integrated steel-plastic production capabilities. Bost delivers tailored solutions, strict quality control, and scalable manufacturing—ensuring every custom worm gears project meets specification and exceeds reliability expectations.

Ordering & Customization

Ordering & Customization is streamlined: provide load, speed, environment, and packaging requirements and our team will recommend materials, geometry, and finishing. Bost supports prototyping, small-batch runs, and full-scale production with technical drawings, testing reports, and after-sales support to ensure your custom worm gears integrate seamlessly into your system.

custom worm gears Display

How do I select the appropriate engineering plastic grade for my product?

Selection should be based on parameters such as load conditions (e.g., pressure/friction), temperature range, medium contact (e.g., oil/acid), and regulatory requirements (e.g., FDA/RoHS). Our engineers can provide free material selection consulting and sample testing.

Can Bost customize modified plastics with special properties?

Yes! We offer modification services such as reinforcement, flame retardancy, conductivity, wear resistance, and UV resistance, for example:

• Adding carbon fiber to enhance stiffness

• Reducing the coefficient of friction through PTFE modification

• Customizing food-grade or medical-grade certified materials

What is the minimum order quantity (MOQ)? Do you support small-batch trial production?

The MOQ for standard products is ≥100kg. We support small-batch trial production (as low as 20kg) and provide mold testing reports and performance data feedback.

What are the core advantages of Bost engineering plastics compared to ordinary plastics?

Bost engineering plastics feature ultra-high mechanical strength, high-temperature resistance (-50°C to 300°C), chemical corrosion resistance, and wear resistance. Compared to ordinary plastics, their service life is extended by 3 to 8 times, making them suitable for replacing metals in harsh environments.

The plastic plug manufactured by Insert molding with stainless steel plate

The plastic plug manufactured by Insert molding with stainless steel plate

The Bost custom PPO flow valve by injection molding

The Bost custom PPO flow valve by injection molding

The Bost custom plastic handle by injection molding with high performance PPS material

The Bost custom plastic handle by injection molding with high performance PPS material

The Bost custom flow meter by injection molding with PES plastic

The Bost custom flow meter by injection molding with PES plastic

The plastic plug manufactured by Insert molding with stainless steel plate

The plastic plug manufactured by Insert molding with stainless steel plate

The Bost custom PPO flow valve by injection molding

The Bost custom PPO flow valve by injection molding

The Bost custom plastic handle by injection molding with high performance PPS material

The Bost custom plastic handle by injection molding with high performance PPS material

The Bost custom flow meter by injection molding with PES plastic

The Bost custom flow meter by injection molding with PES plasticGet in touch with Bost

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

© 2025 BOST. All Rights Reserved.

Scan QR Code

Scan QR Code